Sales enquiry

Air compressor filters are an essential part of every compressed air system. Air compressors rely on the continual flow of clean air, with contaminants needing to be removed for the sake of operational efficiency. Regardless of the machine or its application, dedicated air filters help to maximise performance, prevent equipment damage, and promote industry compliance.

At Cleveland Compressors, our compressed air filter products are designed for industrial air compressors. We are the leading Australian provider of air compressor products, so you can rely on quality products, expert advice, and reliable after-sales service.

If you’re looking for an air compressor air filter for your business, please contact Cleveland Compressors today.

At Cleveland Compressed Air Services, we pride ourselves on providing our Australian clients with the best products and services in the compressed air industry. We offer customised solutions, high-quality products and a friendly company culture built on core values such as integrity, social responsibility and accountability.

As one of Australia’s leading air filter providers, we recognise the importance of providing high-quality air applications and machinery and professional and timely support. If you’re interested in learning more about our range of air filters, please call us today on (08) 9542 3669, email us at info@ccair.net.au or contact us online.

If you are operating your air compressor 3-5 times a week and it has an air filter, it is important to clean it every week. Once you notice the air filter is getting harder to clean out or you notice any holes, it is important to completely replace the filter.

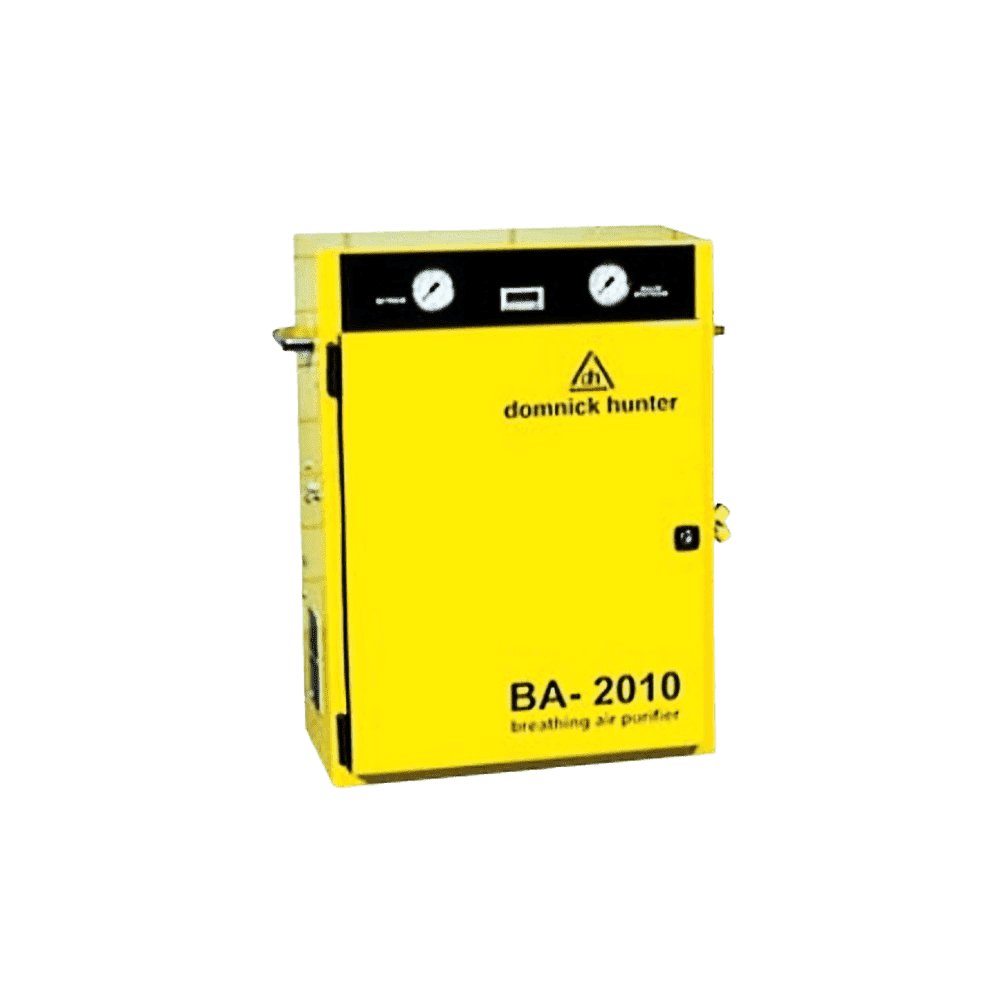

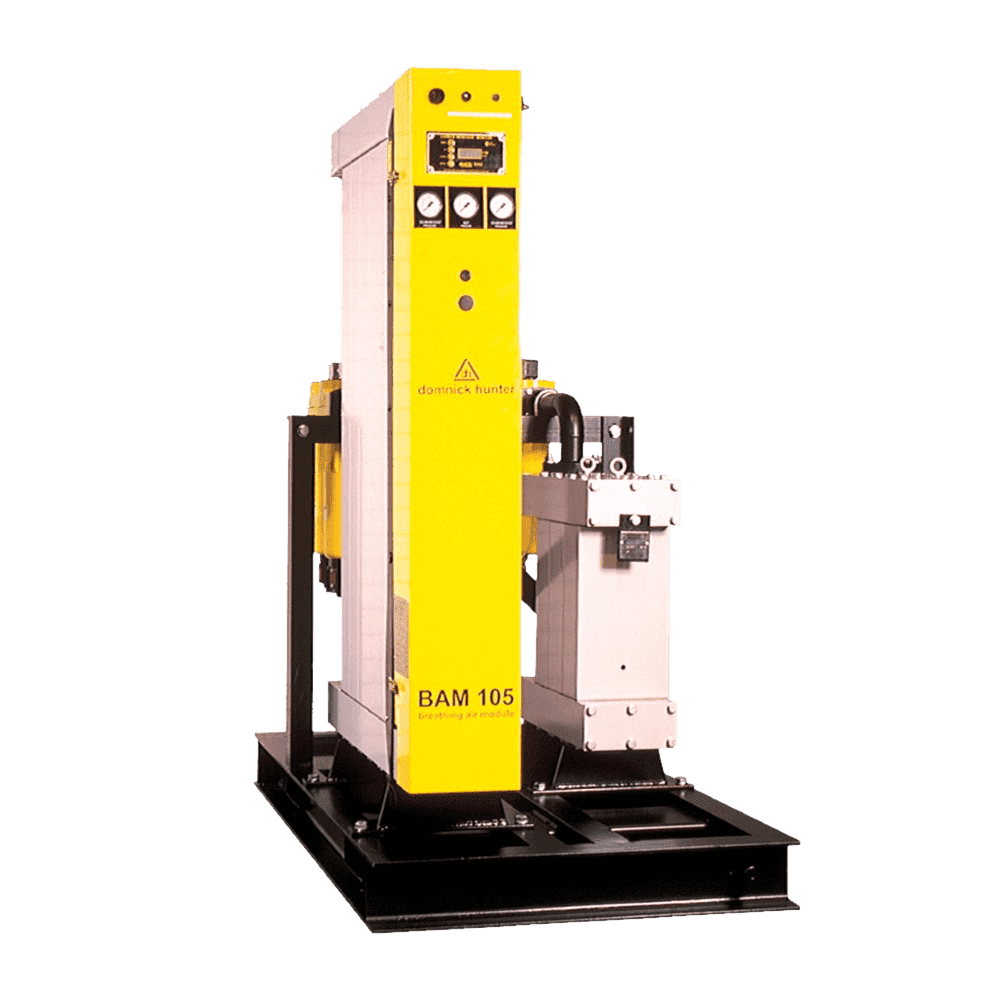

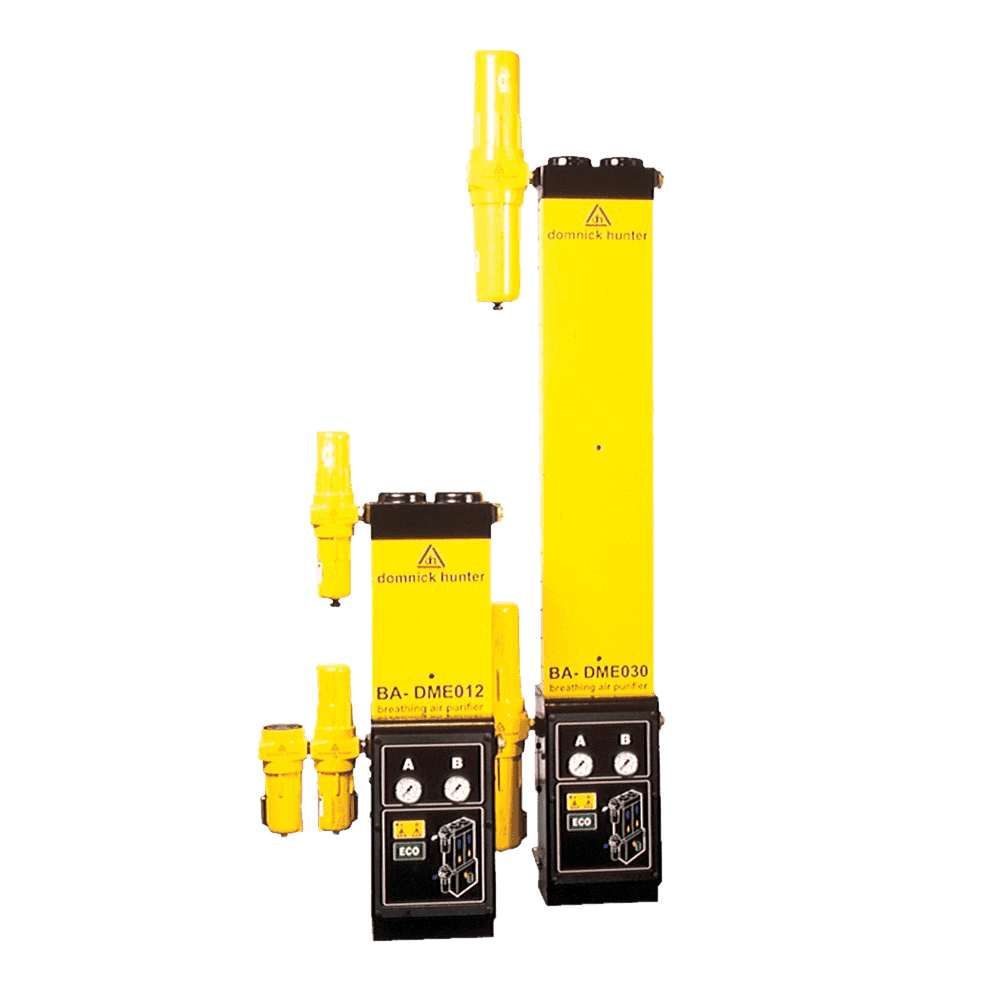

In recent years, employers have become increasingly aware of their responsibility to comply with International Breathing Air Standards. The standards define the quality of breathing air that must be provided to operators working in contaminated environments. Contaminants frequently present in compressed air that threaten the wellbeing of breathing air users are:

For compressed air to be suitable for breathing air applications, it must be properly purified to ensure that it meets the relevant Breathing Air Standard.

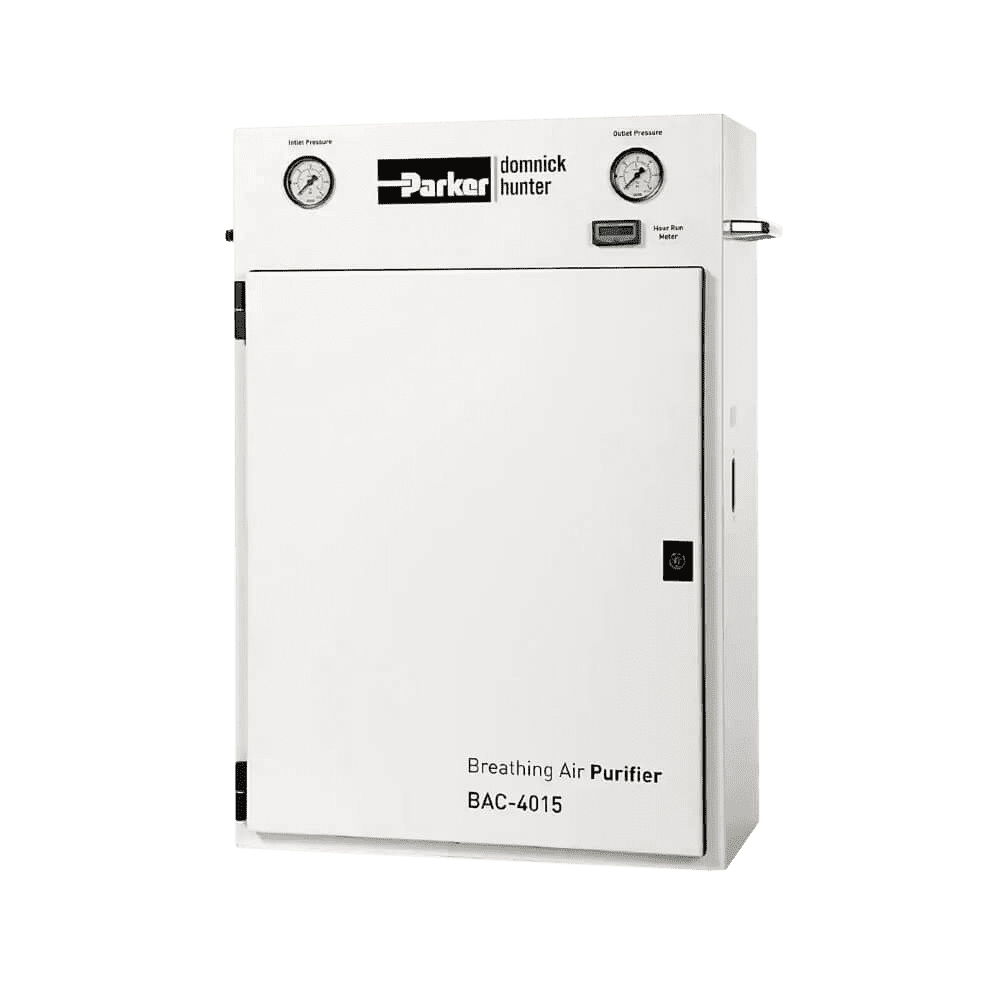

With a wide variety of purification products available, ranging from a simple respirator offering basic protection against low levels of dust particles to self-contained breathing apparatus it is essential that the inhalation risks be fully assessed and a suitable purification product selected. Cleveland Compressed Air Services provides a complete range of breathing air purifiers designed to offer the user protection against some or all of the contaminants that may be present in a compressed air fed breathing air system.

Whatever the application, the quality of the compressed air used for breathing air applications is detailed in International Breathing Air Standards. The applicable standard for the country of use will not only detail the maximum allowable levels of contaminants but also give an indication of the selection criteria for protection devices. If doubt exists about the potential of a possible contaminant then steps must be taken to either monitor the air quality or install a suitable purification device to ensure compliance with the standard.

Many applications exist, ranging from the life-threatening environments of fire fighting, hazardous shot blasting and paint spraying operations, to critical, medical and hospital air requirements.

A compressed air filter is a specially-designed filter made for air compressors. These pneumatic devices play a vital role in many industry sectors, with power converted into potential energy and stored as pressurised air. In order to work properly, air compressors require filters.

Depending on the equipment, these filters are placed either before or after the compression unit, the dryer, or the point of use. The filter then improves the air quality by removing harmful contaminants through compression.

There are many types of air compressor filter, including dry particulate filters, coalescing filters, and vapour removal filters. Dry particulate filters are used to remove desiccant particles after an absorption air dryer, with a membrane material used to remove dust and prevent clogs.

Coalescing filters are designed to separate and capture oil, aerosols, and moisture droplets. Vapour removal filters help to remove gaseous lubricants, with activated charcoal often chosen as the filtering material.

When choosing a compressed air filter for your business, there are lots of things to consider. First and foremost, you need to select a filter that's appropriate for your equipment. At Cleveland Compressors, we review your intended application to help you find the perfect filter. It's important to choose a filter based on the micron rating, with 0.01-micron filters designed to deal with extremely small particles and 1-micron filters dealing with larger liquids and oil particles.

Air compressor filters need to be changed on a regular basis. While the exact timing of these changes depends on the compressor design and its frequency of use, the industry-standard replacement timing is roughly once per year, or every 8,000 hours of operation. Some variables may affect this schedule, however, including improperly sized filtration, high oil carryover, and increased particulate matter.

A well-designed, properly installed, and regularly replaced air filter offers numerous benefits. This simple equipment helps to improve productivity, protect expensive equipment, and ensure the flow of clean and contaminant-free air. When small particles are effectively removed from the compression airflow, equipment is more likely to work properly, less likely to break down, and more cost-effective to operate.

Cleveland Compressors have an extensive range of reliable, high-performing machines for industrial applications from some of Australia's leading brands. No matter your industry, Cleveland Compressors is bound to have the right air compressor equipment to suit your individual air demand needs. If you want to improve your manufacturing and production processes and incredible energy savings, all at the lowest cost, contact Australia's most reliable industrial solutions provider, Cleveland Compressed Air Services by calling (08) 9542 3669, emailing info@ccair.net.au or contacting us online today!

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.