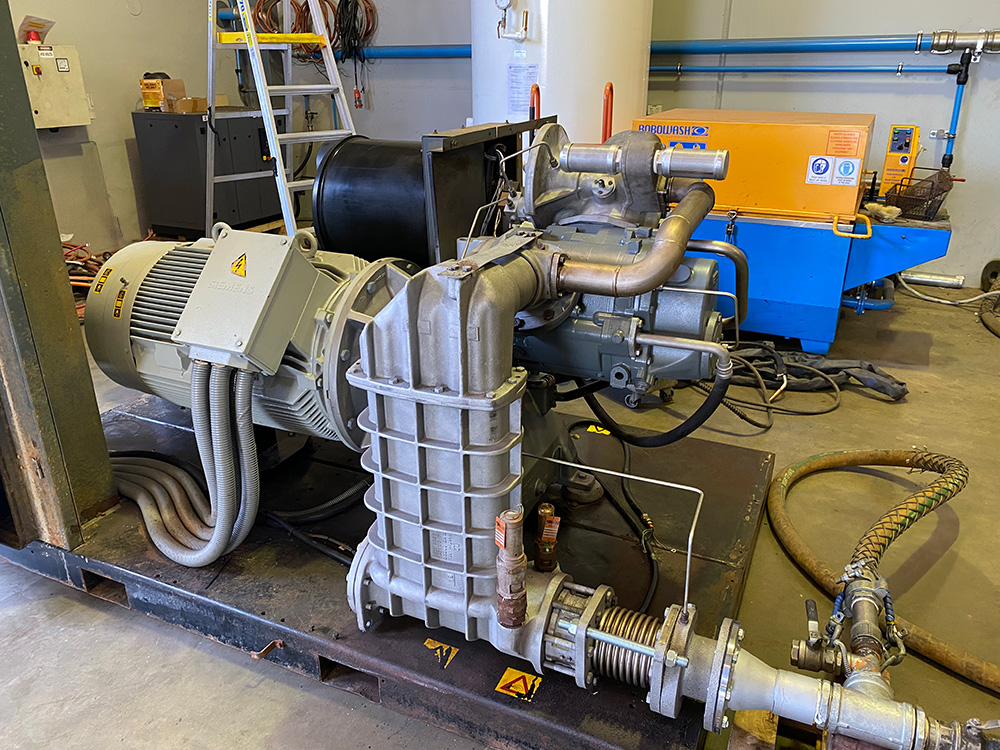

Overhaul and Maintenance Services – Atlas Copco Z Series Compressor and Blower

As an expert in compressed air services, we understand the crucial role of the Atlas Copco Z Series compressor or blower in your operation and the importance of keeping it in top condition.

Our services include overhaul and regular maintenance of your Atlas Copco oil-free Z series compressor and blower, ensuring minimum downtime and maximum operational efficiency. Feel free to contact us to learn more about our service, repair, maintenance and overhaul offerings.

What is the importance of overhauling an Atlas Copco Z Series Compressor?

Overhauling an Atlas Copco Z Series compressor is essential to ensure it’s working efficiently. Regular maintenance helps to prevent unexpected breakdowns and expensive repair costs. It provides optimum air quality, maintaining the quality and reliability of the ZR/ZT/ZA/ZS line’s oil-free compressed air.

Benefits of Regular Maintenance

Regular maintenance of your Atlas Copco equipment extends its lifespan and saves you money in the long run. It helps to identify minor issues before they become acute problems, saving on significant overhaul costs. Regular service includes oil, filter changes, and part replacements, ensuring your compressor remains oil-free and in peak condition.

Signs that an Overhaul is Needed

Signs of a necessary overhaul may include noisy operation, drops in performance levels, increased energy consumption, and constant need for service calls. Contact us at Cleveland Compressed Air Services to schedule an inspection of your ZR/ZT/ZA/ZS Atlas Copco compressor or blower.

Impact of Neglecting Overhaul

Neglecting periodic overhauls may lead to the complete breakdown of your Atlas Copco compressor/blower. This can cause costly downtime, possibly leading to loss of business. Our non-OEM spare parts are available to help minimise the downtime during an overhaul.

Comparing Performance Pre and Post Overhaul

A well-executed overhaul can significantly improve the efficiency and performance of your Atlas Copco Z series compressor. It optimises air quality, reduces energy consumption, and increases the overall life of your equipment.

Cost Implications of Regular Maintenance vs. Major Overhaul

Regularly serviced Atlas Copco compressors often require fewer overhauls, leading to budget savings. Ignore maintenance, and you might be looking at high-cost overhauls in the future. Don’t hesitate to contact us to discuss service and overhaul options tailored to your needs.

What common components require maintenance in the Atlas Copco Z Series Compressor?

- Airend maintenance

- Screw Element replacement

- Filter and oil maintenance

- Electrical system and control panel

- Compressor coolers and heat exchangers maintenance

How do you identify the need for an Atlas Copco Z Series Compressor overhaul?

Noisy Operation

An unusual increase in operation noise level signals an impending performance issue. The noise could be due to worn-out parts, faulty bearings, or misaligned parts in your Atlas Copco Z series compressor. Ensure you engage a professional to examine the cause of the noise and recommend an overhaul as necessary.

Performance Degradation

A noticeable decrease in output pressure or an increase in energy consumption could suggest the need for an overhaul. Other performance degradation signs include a drop in the flow rate or irregular operating cycles.

Oil and Filter Condition Analysis

Regularly inspecting the condition of oil and filters can help you predict machinery deterioration. The presence of metal particles or other foreign substances in the oil can indicate wearing components.

Vibration and Temperature Monitoring

Unusual spikes in vibration and temperature levels are often symptoms of compressor problems. Increasing vibration levels might suggest loose components, misalignment, or imbalanced parts. Excessive temperature, on the other hand, could result from increased friction or leakage in the airend or poor cooler performance.

Predictive Maintenance

Regular preventive maintenance programs like vibration analysis, oil analysis, and IR thermography can help predict the need for an overhaul. In addition to predicting possible failures, these programs can help extend the equipment’s life, minimise unscheduled downtime, and increase operational efficiency.

Increase in Maintenance Costs

An increase in maintenance costs in terms of spare parts and labour can also indicate the need for an overhaul. If the cost of maintaining the compressor starts to exceed that of acquiring a new one, it might be more economical to consider an overhaul or replacement.

Remember that neglecting these warning signs can lead to catastrophic failures, which can further complicate the repair process or even warrant a total compressor replacement.

How do you select the right maintenance service provider for Atlas Copco Z series compressors?

Experience and Expertise

Look for service providers with thorough knowledge and specific experience maintaining Atlas Copco Z series compressors. They should be familiar with the Z series. We have trained technicians here in Western Australia ready to work on your Z series unit. We have been serving our customer base since 1994 and are renowned for our commitment to quality and aftermarket support.

Pricing and Contracts

Ensure you understand all the costs associated with the service, including those not covered in the service contract. Compare the pricing and contracts provided by different service providers to get the best deal.

Customised Maintenance Plans

Your business needs may require specific maintenance tasks not included in a standard contract. Check whether the service provider can offer a customised maintenance plan to cater to your needs. We can tailor our maintenance plans to your operational requirements.

Availability of Emergency Services

Quick response and speedy repairs are crucial in any sudden malfunctions or breakdowns. Look for service providers that offer 24/7 emergency service and have fast response times. Call our 24/7 number if you need an after-hours call out.

Independent Provider

Being an independent service provider, we can help you achieve the best possible outcome for your business as we can provide impartial advice and recommendations for the benefit of your business. Your win is our win as we believe in long-term and mutually beneficial relationships.

Long-Term Maintenance

Check if the service provider offers long-term maintenance plans. This could help in saving costs and reducing downtime.

By considering these factors, you will be able to choose a service provider that meets your needs, provides quality service, and fits within your budget.

FAQs

ZR, ZT, ZA, and ZS are specific models in the Atlas Copco oil-free Z series range of compressors. These models determine the different capacities and specifications of the compressor or blower models, including maximum pressure and flow rates.

At Cleveland Compressed Air Services, we use both OEM and high-quality non-OEM parts for our servicing and overhauls, ensuring we can cater to a wide range of budgets without compromising on the quality of our work. All the work comes with our quality guarantee.

Our services are available both as one-time services or as part of an ongoing service agreement. For more information about these options, please get in touch with us directly.

Our team at Cleveland Compressed Air Services provides a range of services including preventative maintenance, repair, full overhaul, and parts replacement for Atlas Copco Z series models. For an itemised breakdown of our services, please contact us.

Absolutely. All our services are fully certified and comply with all relevant industry regulations. We place a heavy emphasis on safety and quality in all aspects of our operations.

For more information, please visit our website or contact us directly via telephone or email. Our team will be more than happy to assist with any enquiries you may have.