Enquiry Form

At Cleveland Compressed Air Services, we aren’t just a distributor of compressed air equipment. We don’t just provide products. We provide custom-built solutions, which we back up with quality products, quality installations, and quality service and repairs. Our clients don’t just get air compressors, they get the best solution to their problem, the equipment and product to fix the problem, and the 24/7 assistance to maintain the fix and to ensure that their business operates at peak productivity– all delivered through one window. Our advice is always geared to suit your specific needs.

We also don’t pigeonhole our clients. We know that no two businesses are completely alike and that in fact, a company’s competitive edge arises from how it does things differently from the others. The products and service contracts must be the best solution for that company’s business practices, budget, and objectives.

On a micro level, we also know that the equipment that will optimise one set of operations–or specific site–must be the best option in that particular environment.

That’s why Cleveland Compressed Air Services is able to deliver a customised solution that makes your operations more energy and cost-efficient, more productive, and in the end, more profitable. Our business is making your compressed air project run better so your business runs better. Our expert service technicians carefully consider all the physical conditions and the other details of operation so they provide their expertise on things like:

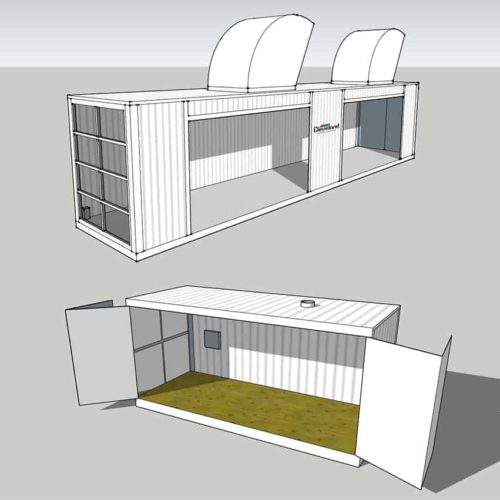

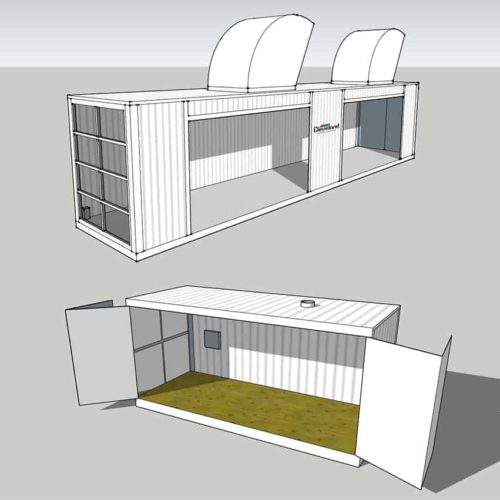

You are making a big investment when you purchase compressed air equipment and compressed air forms a key element of your operations. You need to make sure that investment is protected from damaging elements, including wind, water and UV radiation. Cleveland Compressors offers containerised solutions to shield it from damage.

Our containerised solutions will protect your compressed air compressor equipment, even in cyclonic regions. Here are some reasons to use our solutions:

Your containerised solutions are easy to set up. You simply need to install them on level ground and fasten them in place. If you are installing them in a cyclonic area, you can also anchor them for additional support.

Our clients are diverse. Their projects can have very different needs. Each one brings a unique set of challenges and objectives, requiring custom-built solutions tailored to their specific needs. Here are just some examples of custom solutions we have been proud to deliver:

Absolutely, tailoring custom solutions is our specialty. Our expert team is on hand to offer advice and develop the best solution to meet your unique operational requirements. From initial consultation to final delivery, we work closely with you to ensure your custom-built system meets your specifications and performance goals.

The lifespan can vary depending on usage and maintenance, but with proper care, our custom air compressors are built to last and provide efficient service for many years. Coupled with our comprehensive after-sales support and maintenance services, you can expect a long-lasting, high-performing compressed air solution.

Certainly, we can offer advice on the best upgrade path and provide components that will integrate seamlessly into your existing system. Whether you're looking to improve efficiency, add new features, or extend the lifespan of your system, we have custom-built solutions that can be delivered to meet your specific needs.

Our team of experts is available to provide advice based on your specific requirements, helping you find the best solution that suits your operational needs and budget.

Cleveland Compressors have an extensive range of reliable, high-performing machines for industrial applications from some of Australia's leading brands. No matter your industry, Cleveland Compressors is bound to have the right air compressor equipment to suit your individual air demand needs. If you want to improve your manufacturing and production processes and incredible energy savings, all at the lowest cost, contact Australia's most reliable industrial solutions provider, Cleveland Compressed Air Services by calling (08) 9452 3669, emailing info@ccair.net.au or contacting us online today!

Give us a call to find out how we can provide you with a customised compressed air solution to suit your requirements. You can also contact us online with any questions.

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.