Enquiry Form

Compressed air purification equipment must deliver uncompromising performance and reliability while providing the right balance of air quality with the lowest cost of operation.

Our range includes:

Many manufacturers offer products for the filtration and purification of contaminated compressed air, which are often selected only upon their initial purchase cost, with little or no regard for the air quality they provide, the cost of operation throughout their life or indeed their environmental impact.

Compressed air dryers are used in a number of industries such as manufacturing and engineering. When purchasing purification equipment, delivered air quality, the overall cost of ownership and the equipment’s environmental impact should always be considered. As one of Australia’s leading providers of compressed air products and services, Cleveland Compressed Air Services can help you find the air compressor dryer that can help take your business to the next level.

At Cleveland Compressed Air Services, we pride ourselves on providing our Australian clients with the best products and services in the compressed air industry. We offer customised solutions, high-quality products and a friendly company culture built on core values such as integrity, social responsibility and accountability.

As one of Australia’s leading compressed air dryer providers, we recognise the importance of providing high-quality air applications and machinery and professional and timely support. If you’re interested in learning more about our range of air dryers, please call us today on (08) 9542 3669, email us at info@ccair.net.au or contact us online.

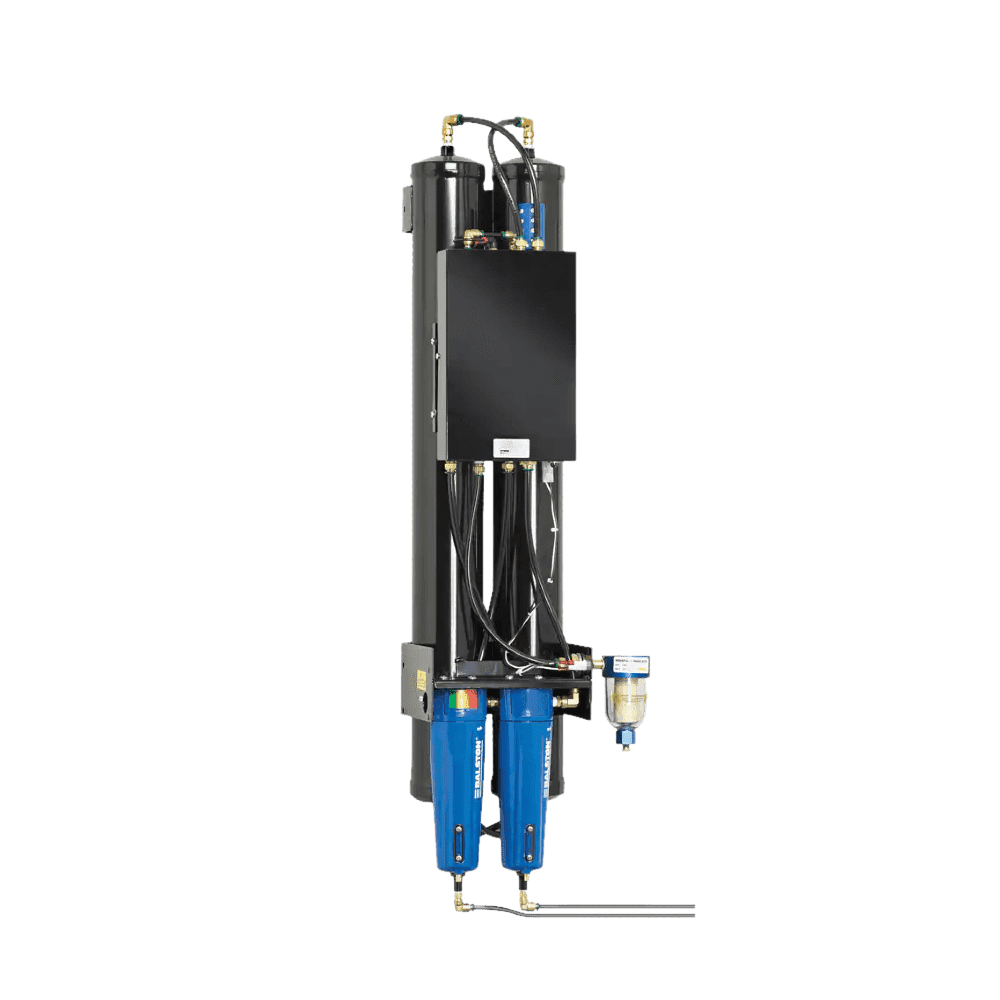

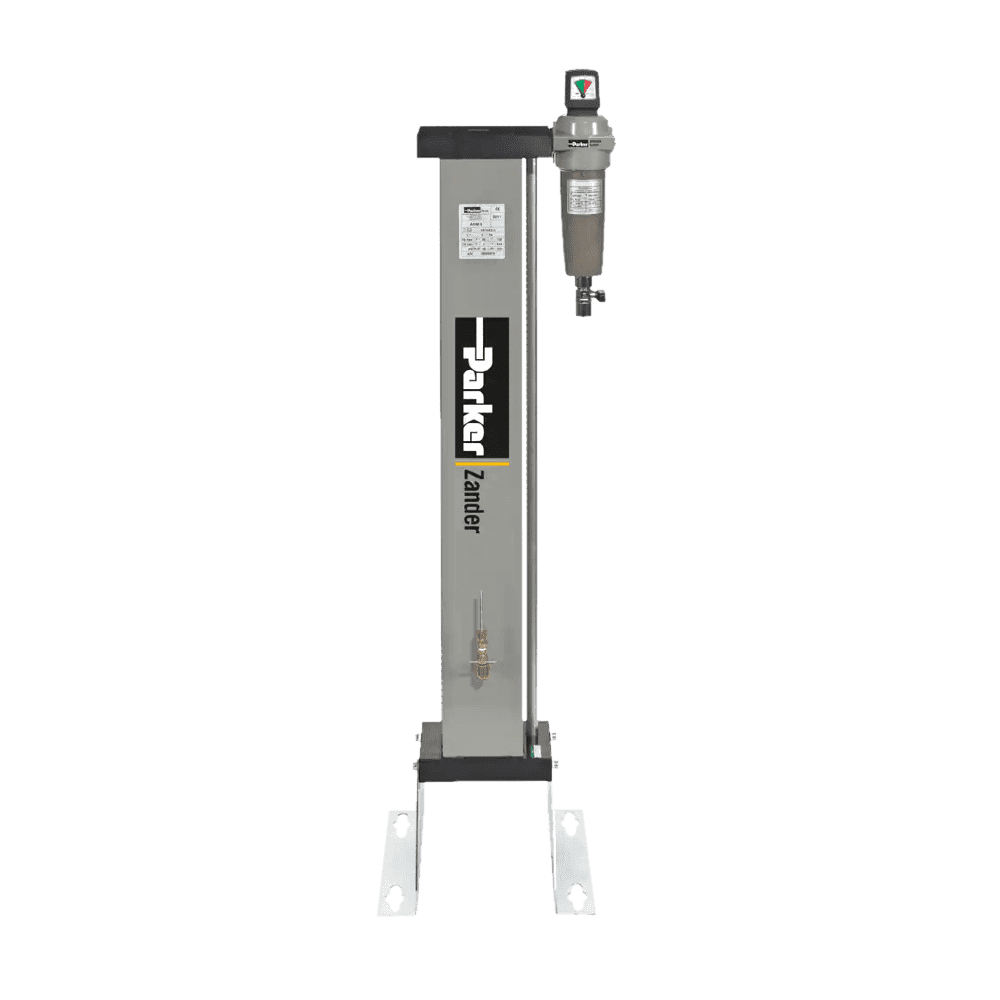

A membrane air dryer uses a filtration system to remove contaminants and water from compressed air. This process of separating liquid from the vapour is known as "vapour recompression". Membrane air dryers work by drawing in moist, warm, and contaminated air that passes over an absorbent material. The membranes then allow for the separation of heat and moisture from the gas stream resulting in drier, cleaner and more pressurised gas being delivered to downstream equipment such as air filters or turbines.

Membrane air dryers can be used for various industrial processes such as food dehydration or chemical production. They provide a reliable, energy-efficient and space-saving alternative to some other air dryer types. This type of air dryer is often found in pharmaceutical plants, paper mills, and textile factories.

A compressed air dryer is a machine built to significantly reduce or remove moisture and water vapour that is inherently present in compressed air. Water vapour needs to be reduced or eliminated as once the moisture in the compressed air reaches the dew point (under the right conditions), it can condense into a harmful fluid.

The effects of liquid or water on the parts of refrigerated compressed air dryers can be corrosive, damaging and expensive. If the condensate is left to accumulate inside the compressor unit, it could slowly dry into the metal surfaces of the different moisture-sensitive motor components, leading to rusting. In turn, the compressor could start to drag, malfunction and eventually overheat due to corrosion.

This is why compressed air dryers are used with air compressors. Doing so prevents condensation that could affect your machines, tools, piping and product quality and creates a safer workplace for your employees.

A compressed air dryer is a filter system explicitly designed to eliminate moisture or water content that’s naturally present in compressed air. Compressed air dryers are used in conjunction with compressed air systems to prevent excess liquid and condensate from causing damage to tools and equipment and ensure the safety of processes dependent on compressed air.

Without compressed air dryers, the wet air can lead to tank and piping corrosion, the clumping of blasting media (e.g., plastic pellets and sugar sand), fogging on painted surfaces and the emulsification of grease usually found in cylinders.

There are several compressed air dryers, but the four primary types are refrigerated dryers, desiccant dryers, chemical dryers and membrane air dryers. The type of compressed air dryer you use depends primarily on the industry or application.

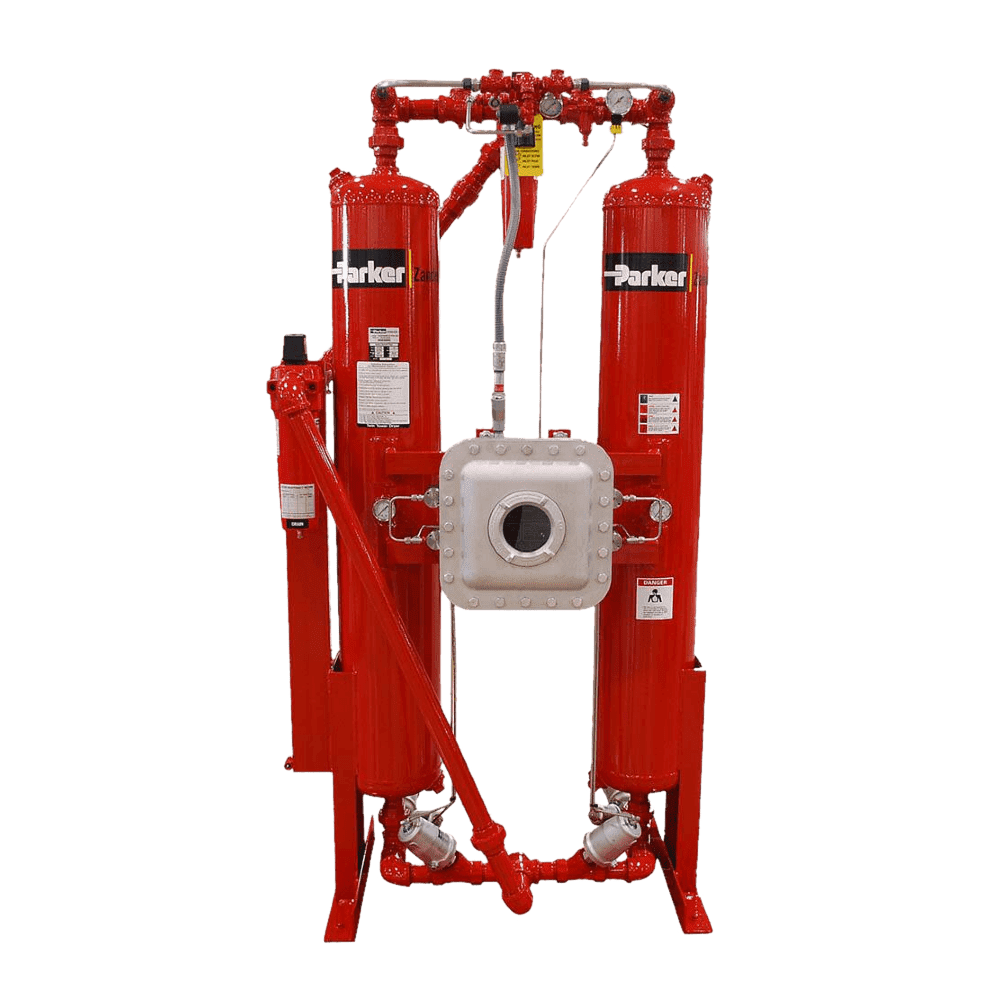

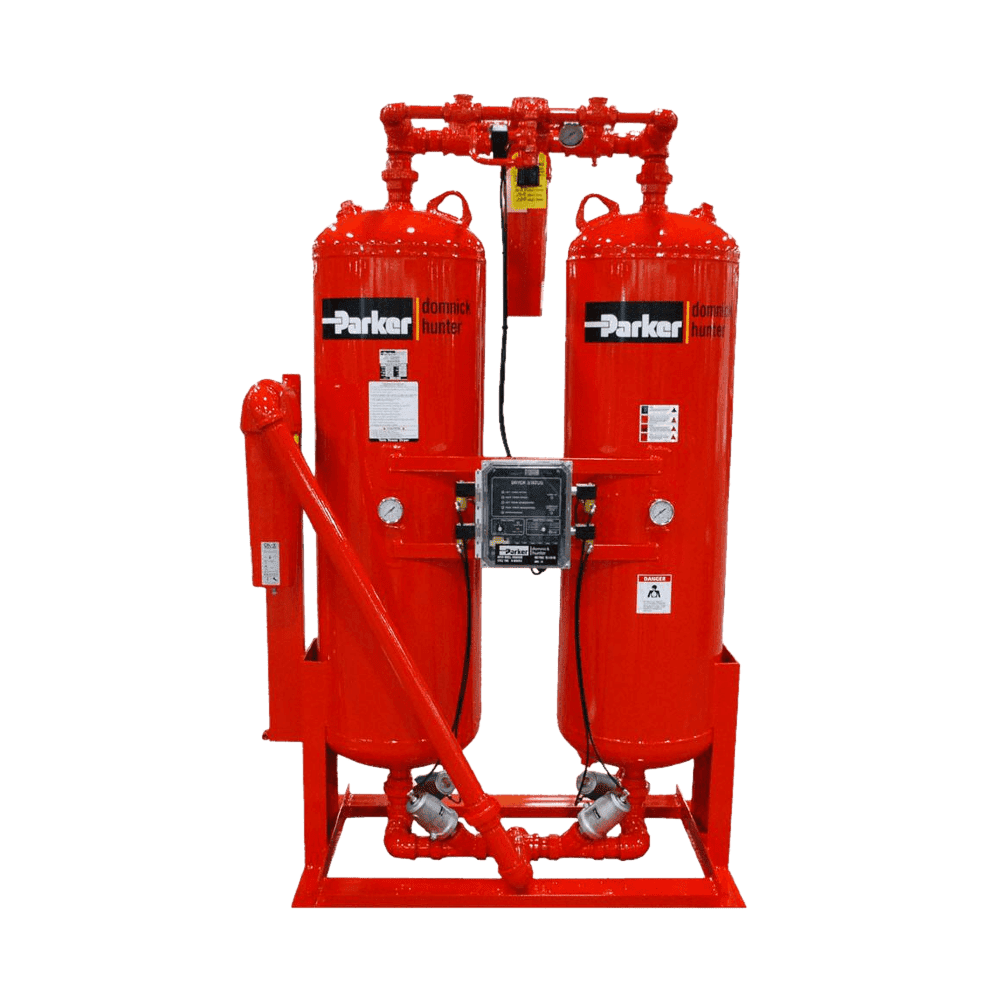

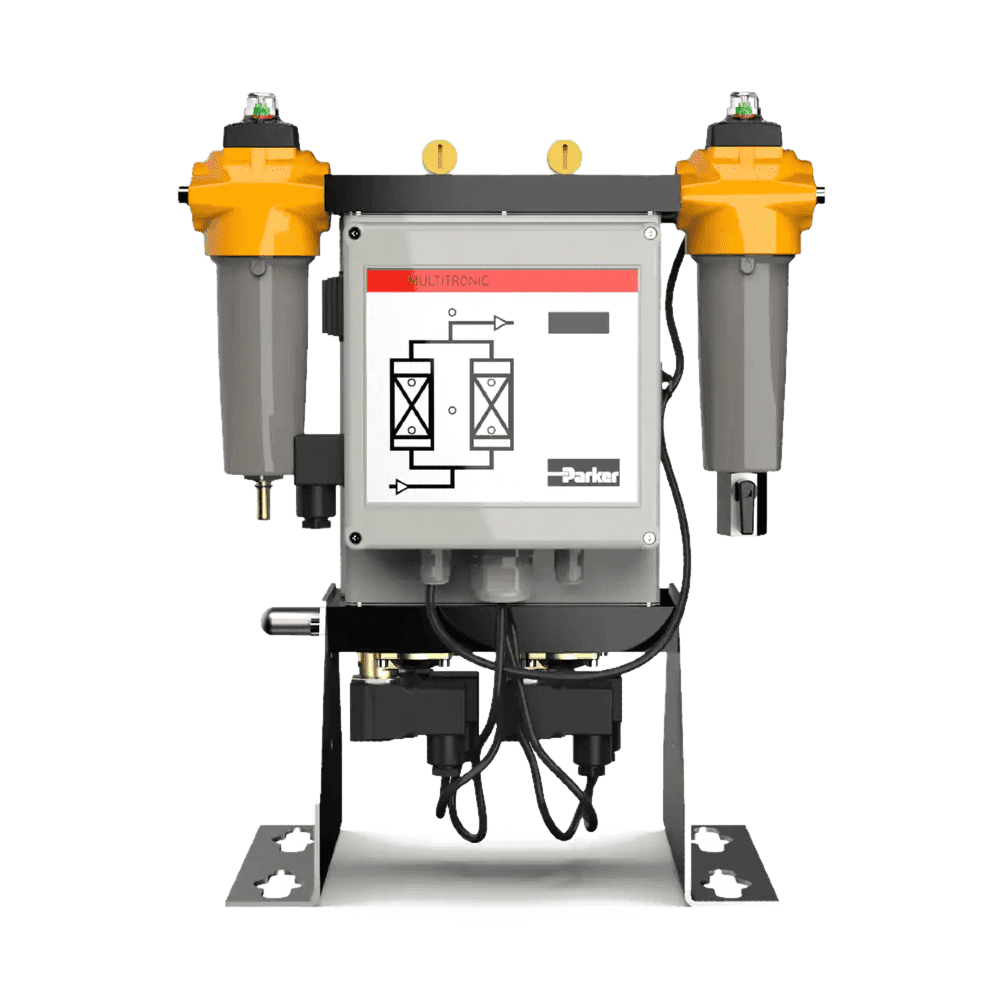

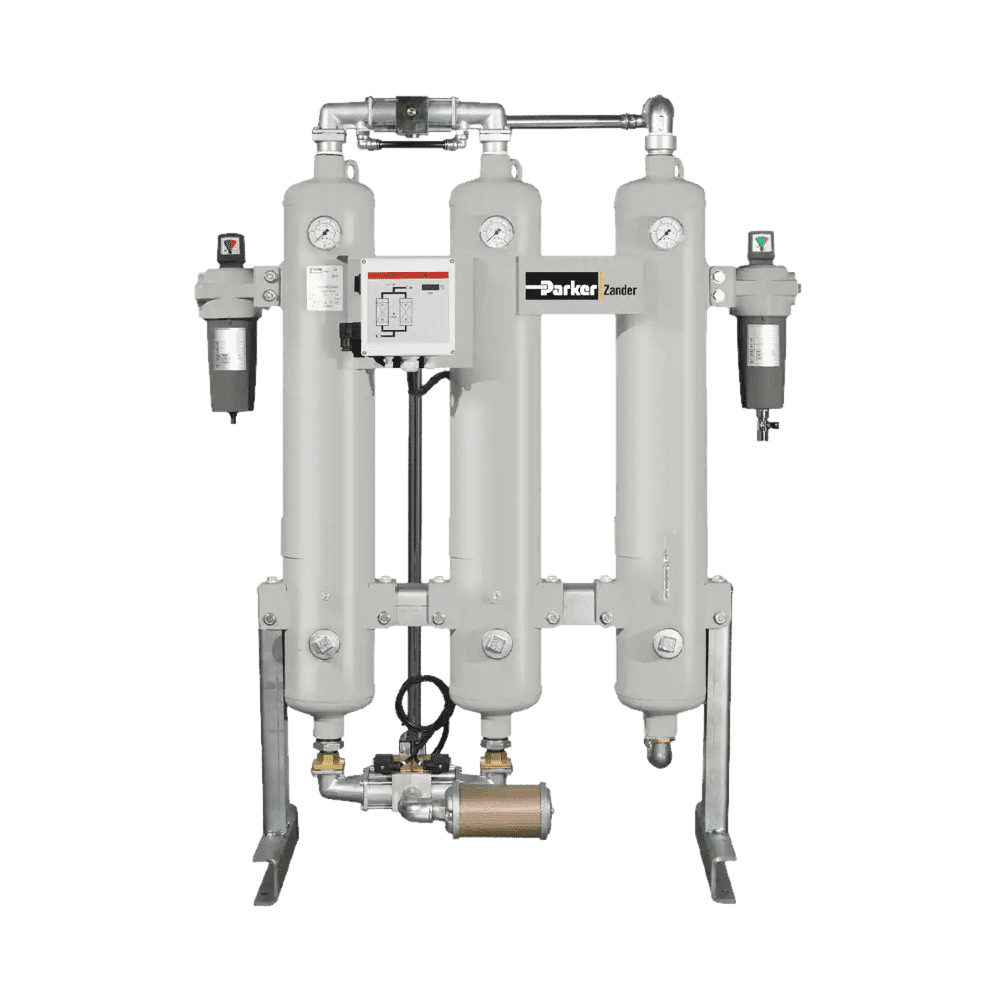

With moisture being an inherent factor in compressed air, it’s crucial to eliminate excess amounts for the right air quality. This is to ensure the efficiency of processes and protect sensitive equipment. A desiccant dryer (aka ‘adsorption dryer’) is a type of industrial equipment designed to eliminate any water in the air that’s channelled through it. It uses desiccant materials to do its job and is primarily composed of two towers that guarantee continuous air-drying cycles.

There are different types of compressed air dryers, and they also operate in different ways. Refrigerated compressed air dryers, desiccant air dryers, membrane air dryers, speciality gas and liquid dryers, and deliquescent air dryers are the standard forms of air dryers used with air compressor systems.

Your specific application or industry will determine which type of compressed air dryer you should use. In turn, the kind of dryer you use will determine how the machine works and the air quality it produces.

Industries that utilise compressed air dryers include the naval, chemical and petrochemical, nuclear power, pharmaceutical, manufacturing, and food and beverage sectors. However, since there are specific types of air dryers, they also vary significantly in terms of their industrial applications.

Desiccants are adsorbent materials that possess a high affinity to water and hygroscopic properties. This means that desiccant materials pull and hold water molecules from the inlet air within themselves to maintain an immediate dry environment effectively. However, desiccants can and do become saturated. When this happens, the desiccant material is again dried through the use of compressed or hot air through an electric heater.

Activated charcoal, activated alumina, silica, aluminosilicate minerals or zeolites, desiccant beads, calcium chloride and calcium phosphate, are some examples of commonly used desiccant materials. They are utilised in both domestic and industrial compressed air drying, as well as other applications.

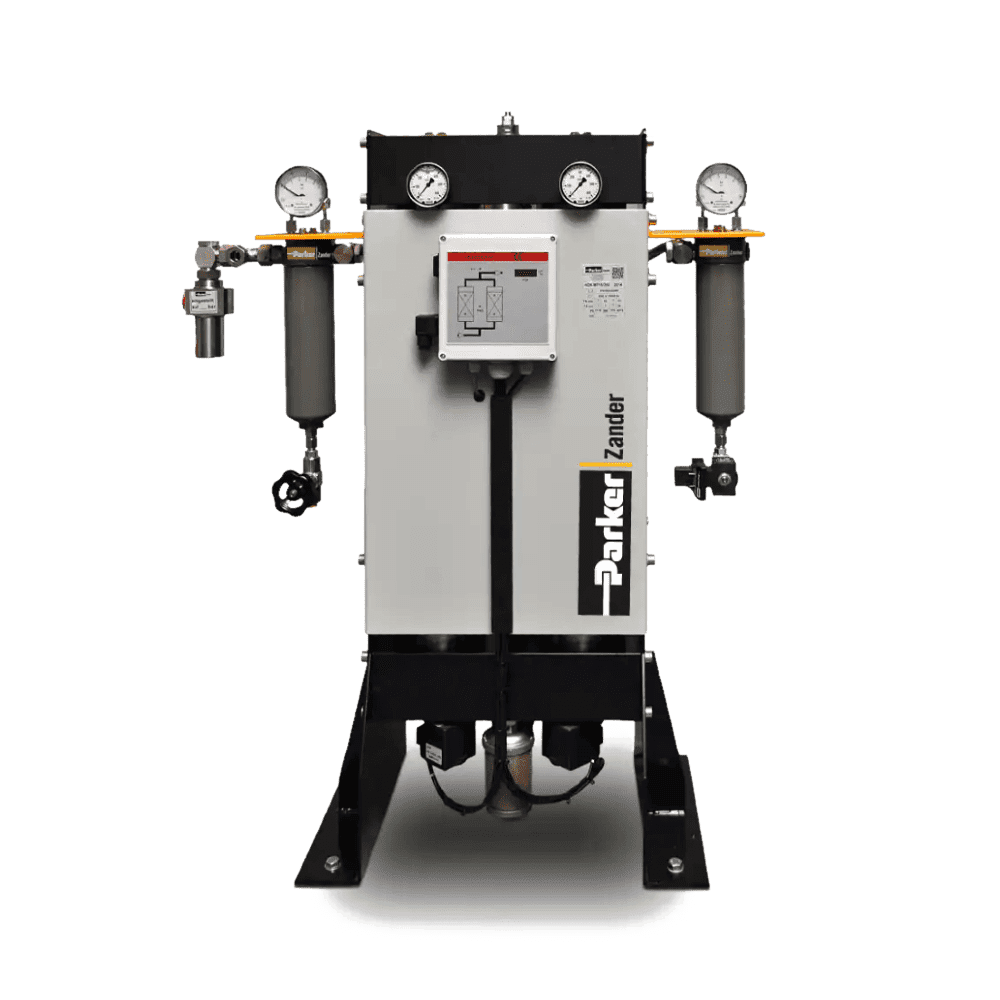

The refrigerated air dryer is one of the most common air dryers used with compressed air systems. In fact, refrigerated dryers are the most popular air dryers you’ll find being used with industrial compressed air systems. One reason for this is that refrigerated air dryers are reasonably priced. They are also compatible with setups that are not operating under extremely hot conditions and where there is no requirement for exceptionally high drying capacity.

A refrigerated compressed air dryer uses a simple mechanism comprising a single or several heat exchangers that work to cool the hot compressed air. The heat exchangers condense out most of the warm wet air from the compressed air and remove it using a separator equipped with an automatic drain.

When choosing your air dryer, it is important to consider factors such as:

If you’re unsure which air dryer is most suitable for your needs, our team is on hand to help you choose the perfect one.

Compressed air dryers are intended to be used in tandem with air compressors. They are often used in applications where water vapour can damage machinery and equipment. A compressed air dryer can be used in various situations, including medical applications, food and beverage industries, construction and more. At Cleveland Compressed Air Services, our machines are available in a wide range of sizes and configurations to suit virtually every application requirement.

To get the right refrigerated air dryer that would provide you more years of use, make sure you consider the following:

When choosing a desiccant compressed air dryer, there are certain factors you need to take into consideration:

Aside from considering the above items, manufacturers of air dryer systems usually provide corrections that apply to various operating conditions. However, it's best to work with experts that can help you calibrate your system according to your specific requirements.

At Cleveland Compressed Air Services, we can help you configure your air drying system to ensure it is optimised to provide you with the exact drying solution for your business.

In general, businesses or industries that use compressed air systems can benefit from using a refrigerated air dryer.

Some industries that utilise refrigerated air dryers include healthcare, pharmaceuticals, chemical manufacturing, and food and beverage. Refrigerated air dryers are particularly commonly used in beverage carton processing and for transferring chemicals in sterile environments.

However, there are other types of compressed air dryers, so it’s crucial to know the needs of your business to determine whether refrigerated air dryers will be the solution to your compressed air needs.

Desiccant dryers are commonly used in a range of applications that utilise compressed air. In the oil and gas industry, desiccant dryers are used in processes like oil recovery, petroleum refining and transport, as the equipment used is susceptible to damage due to moisture.

While desiccant dryers are known to deliver much dryer air than refrigerated dryers, they do cost more to purchase, operate and maintain. Therefore, it makes sense to use them for highly sensitive applications or production processes and equipment. Desiccant dryers are also a practical choice in setups where refrigerated dryers may not work optimally, such as in high-dust or high-heat environments.

We are proud to offer a wide range of compressor air dryers suitable for a variety of applications and industries. All of our air dryers offer benefits such as:

Refrigerated air dryers are suitable for various industrial applications where moisture reduction or elimination is required. Aside from this, they offer other benefits:

As mentioned earlier, desiccant dryers produce air that’s substantially dryer compared to refrigerated air dryers. Moreover, desiccant dryers also take less time to dry the air than most dryers, so they’re ideal for operations where time savings are crucial.

Pressure dew point is the temperature at which water vapour in the air becomes saturated with water and condenses to form liquid dew. The higher the dew point, the more moisture there is in the air. It is a common measurement to assess how much moisture will be present in an environment over time.

Cleveland Compressed Air Services has been around since 1994. We’ve been part of Australia’s commercial and industrial landscape, providing compressed air solutions to a wide range of industries and businesses.

We not only offer a comprehensive selection of refrigerated compressed air dryers and components but also supply air blowers and industrial chillers. Moreover, our highly experienced team of professional technicians have the familiarity and capabilities to handle all your repair, maintenance and other servicing needs.

Flow rate is the amount of fluid that passes through a given point at a specific time. Technically, it's the volumetric airflow rate, which means how much volume flows past a point per unit time. This can be measured in cubic feet per minute (CFM). The more CFMs, the more air your unit will disperse throughout your space.

There are several air-drying systems available on the market, but they’re certainly not created equal.

In deciding on your air dryer system, it’s best to get the advice of a trusted firm like Cleveland Compressors.

We have been providing high-quality compressed air solutions and services to our Australian clients since 1994. With our extensive knowledge of air-drying products and their applications, we can help you decide whether you need a desiccant air dryer system for your business.

If you have other questions or would like to know more about our range of air dryers, please get in touch with us online or call us on (08) 9542 3669. You may also send an email to info@ccair.net.au.

Cleveland Compressors have an extensive range of reliable, high-performing machines for industrial applications from some of Australia's leading brands. No matter your industry, Cleveland Compressors is bound to have the right air compressor equipment to suit your individual air demand needs. If you want to improve your manufacturing and production processes and incredible energy savings, all at the lowest cost, contact Australia's most reliable industrial solutions provider, Cleveland Compressed Air Services by calling (08) 9542 3669, emailing info@ccair.net.au or contacting us online today!

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.