Enquiry Form

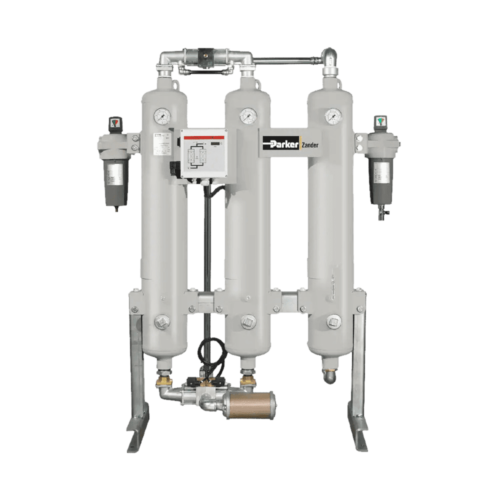

DOWNLOAD THE PARKER ZANDER KA-MT 1-8 ADSORPTION DESICCANT AIR DRYER PDF

FEATURES AND BENEFITS

ADVANTAGES

ENERGY SAVINGS

SIZING AND SELECTION

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.