Enquiry Form

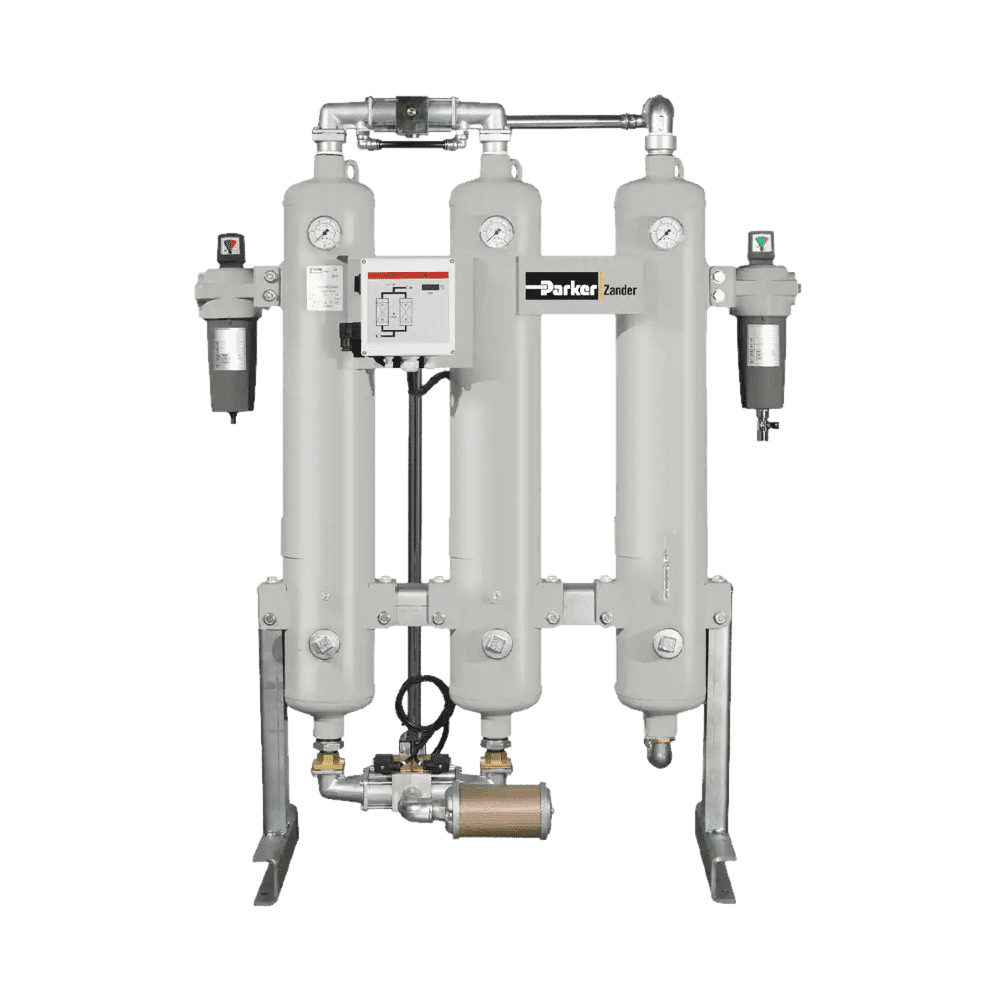

DOWNLOAD THE ECODRY ZME SERIES & ECODRYMAX SERIES MODULAR HEATLESS ADSORPTION DRYERS PDF

FEATURES AND BENEFITS

APPLICATIONS

The use of adsorption dryers with heatless regeneration is preferred in the following applications:

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.