At Cleveland Compressors, we are proud to be Western Australia’s largest independent provider of air compressors, compressor products and services.

Our range of air compressors is especially popular and used in various industries for purposes including tooling, instrumentation and other process applications as an energy source.

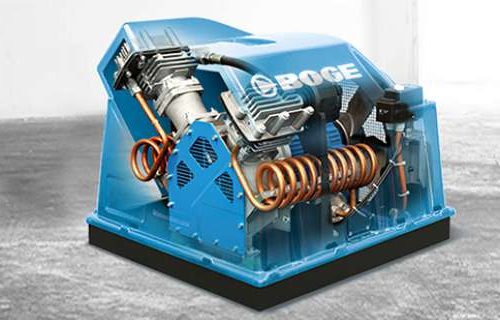

Our range of BOGE oil-free piston air compressors is offered as part of our wider range of oil-free air compressors. Like the others, it provides customers looking for an alternative to oil-injected air compressors with top-quality equipment that they can rely on. Here, we’ll look at the models that we have available in greater detail.

Known for its reliable precision and high-quality standards, BOGE offers the following variants in their oil-free piston range:

- ASO(L)

- BSO(L)

- BSO(L) DM

- K Series

- K Booster

- PO Series

ASO / ASOL Series

Features

A base mounted piston compressor unit that is able to provide an individual solution to your compressed air requirements. Also available as a super-silenced model.

Benefits

- Lower costs and less time spent when extending your system

- Energy cost savings due to base-load and peak-load compressors

BSO / BSOL Series

1. Receiver Mounted Compressor

Features

Its modular assembly system allows the selection of individual compressors and receiver sizes depending on the application. Also available as a super-silenced model.

Benefits

- No special foundations required

- Most economic unit designed for each compressed air demand

- Customised solution for each application

- Super-silenced model that can be installed directly in the workplace

- Galvanised pressure receiver

2. Duplex Compressor Package – Receiver Mounted

Features

Works economically when compressed air demand fluctuates greatly.

The compressors can be switched as base-load or peak-load machines, or as load and standby-compressors with 100% reserve capacity. Also available as a super-silenced model.

Benefits

- Energy cost savings by avoiding high power peaks

- Stand-by compressor for expansion, peak demand and air supply during maintenance periods

- Uniform loading

- Super-silenced model that can be installed directly in the workplace

- Galvanised pressure vessel

BSO / BSOL DM Series

1. Compressor Unit – With twin air receivers

Features

A complete system with the compressor installed directly onto twin air receivers.

2. Compressor Station – With twin air receivers and membrane dryer

Features

Provides simple compressed air drying with:

- No condensate discharge

- No moving parts

- No electrical connections

- No CFCs

- Dry compressed air

- No additional space required for the dryer

3. Compressor Station – Super-silenced

Features

Comprises a compressor, twin air receivers and membrane dryer (optional) in a super-silenced housing. Can be installed directly in the workplace.

Benefits

- Minimum installation costs

- Practically maintenance-free

- Energy cost savings

- A positive contribution towards protecting the environment

- Galvanised pressure receiver

- No foundations

- Minimum space required

K Series

Features

In an entirely new and compact design, the K series represents the latest compressor technology for oil-free air compression with minimal wear.

Oil level checks are no longer required and neither are belt replacements. K-type models are designed for one-stage compression up to 10 bar and two-stage compression up to 40 bar.

Benefits

- Reduced downstream air treatment costs during operation

- Condensate treatment eliminated

- Reduced service time costs

- Reduced service component costs

- Modular design means easy expansion

- K means reduced energy consumption

- Completely ready to install

K Booster

Features

Takes in pre-compressed and pre-treated compressed air from an existing network or from a low-pressure compressor and compresses it to the required higher final pressure.

For anyone who wants to compress to maximum pressure in an economic and oil-free way!

Benefits

- Oil-free booster compressor

- From an inlet pressure of 10 bar to a final pressure of 40 bar (maximum)

- Unique in the category up to 5.5 kW

- No treatment needed

- Low-wear operation

- BASIC-control and IE3 motor for energy-efficient operation

- Reciprocating duct according to pushrod principle

- Intelligent cooling air duct

- Compact construction

- Absolutely oil-free generated compressed air

- Ideal for sensitive application areas

PO Series

Features

The completely oil-free piston compressors in the new series provide high quality compressed air with exceptional efficiency.

With special attention to low-wear operation, extremely compact footprint with the closed hood concept, high operational reliability has combined with environmental friendliness. PO series meets the requirements of the RoHS Directive (2002/95 /EC).

Benefits

- Significant efficiency gains and higher free air delivery

- Reduced noise

- Compact design with easier maintenance

- Low-wearing

- Reduced downstream air treatment costs during operation

- Modular design means easy expansion

- Ready to install