Enquiry Form

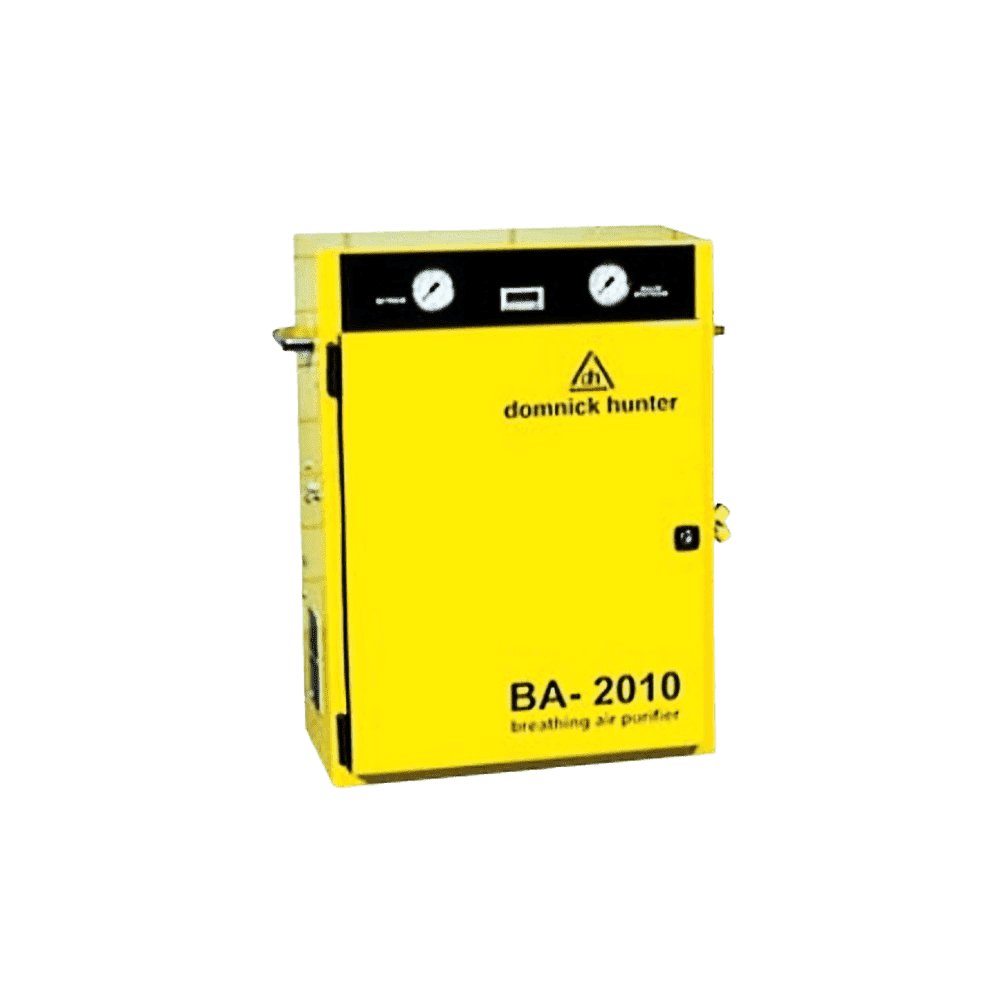

The Parker Domnick Hunter BA-DME Breathing Air Purifier System consists of several stages of contaminant removal. The use of adsorption materials, namely activated desiccant and carbon removes water vapour and oil vapour/odours respectively. The desiccant material is contained in a pressure swing adsorption dryer that delivers a constant pressure dewpoint of -40°F (-40°C). Downstream of the desiccant dryer, a catalyst converts carbon monoxide to carbon dioxide by catalytic conversion. A final dust filter captures any particulates carried over from the adsorption materials.

The BA-DME Breathing Air Purifier System removes the following contaminants: solid particles, oil mists, oil vapours, odours and fumes, water mists, water vapour, carbon monoxide and carbon dioxide.

A medical air supply is a vital part of every hospital infrastructure and is one of the few medicines that is manufactured on-site. Parker Domnick Hunter BA-DME and BAM Breathing Air Purifier Systems provide integrated filtration and adsorption stages to deliver the air quality required for medical applications. Parker Domnick Hunter Breathing Air Systems have been tested to the European Pharmacopoeia Medical Air Standard, which is more stringent than OSHA Grade D standards.

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.