Enquiry Form

We take pride in our commitment to quality, integrity, and accountability. Cleveland Compressed Air Services offers not only premium products but also bespoke support. Our systems feature corrosion-resistant materials and designs focused on energy conservation, ensuring lasting value for your investment.

Our commitment to quality and customer satisfaction has made us one of Australia’s leading air piping providers. We use corrosion-free materials, such as aluminium, to ensure clean and efficient operation in all applications. We understand the importance of efficient air compressor systems, designed to optimise airflow, minimise pressure drop, and reduce operational costs. Whether you’re in mining, medical, construction, or manufacturing, our team is here to deliver expert guidance and timely, professional support.

Designing a compressed air piping system is a meticulous process that requires careful planning to ensure optimal performance and longevity. The goal is to create a system that minimises pressure drop, reduces air flow restrictions, and prevents corrosion. Here are the essential steps to consider:

By following these steps, you can design a compressed air piping system that delivers reliable performance and efficiency.

The efficiency and reliability of a compressed air piping system depend significantly on the quality of its components. Here are the key components to consider:

By investing in high-quality components, you can enhance the performance and reliability of your compressed air piping system.

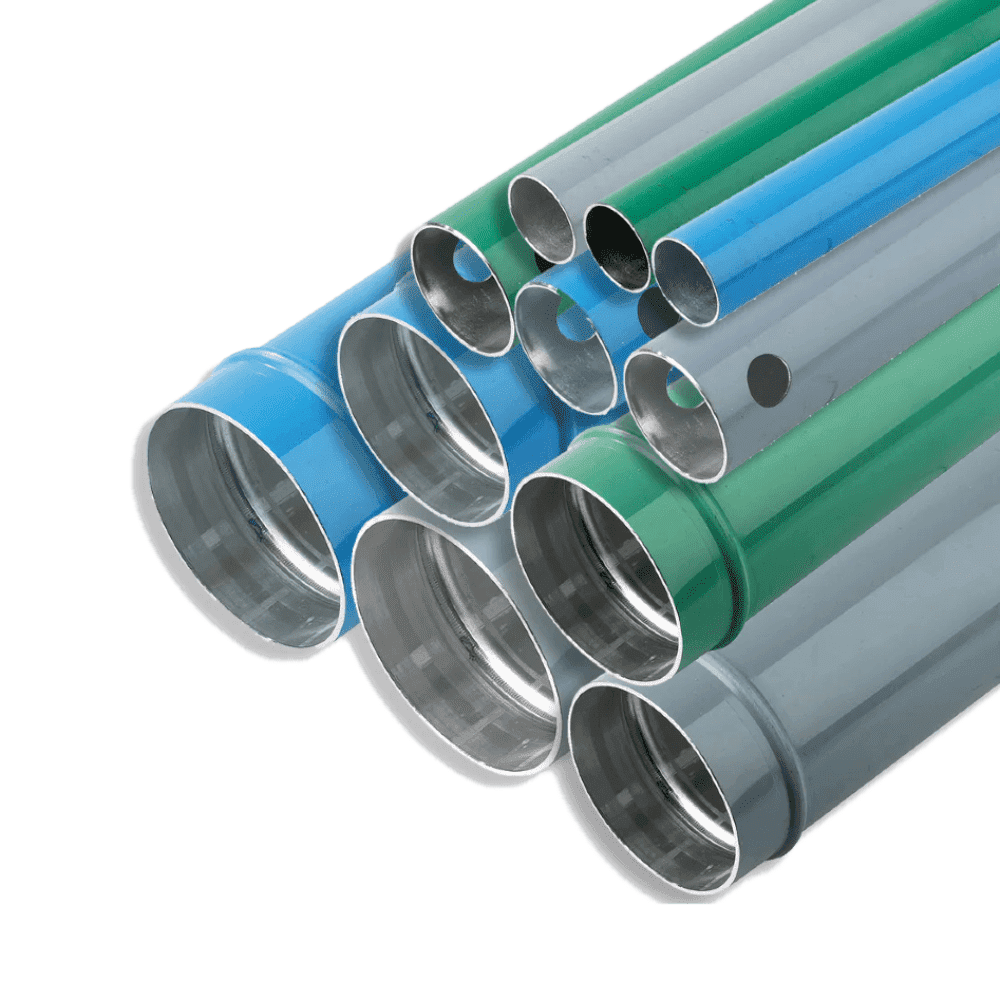

Aluminium compressed air pipe solutions offer numerous advantages over traditional piping materials. Here’s why aluminium pipes are an excellent choice for compressed air applications:

Choosing aluminium pipes for your compressed air system ensures durability, efficiency, and ease of maintenance.

Compressed air piping systems are essential across multiple industries, offering reliable and efficient power for various specialised applications. Here’s how these systems contribute to specific sectors:

These applications showcase the versatility and critical value of high-quality compressed air piping systems, delivering dependable, energy-efficient solutions tailored to the needs of demanding environments across key industries.

Ensuring quality and safety in compressed air piping systems is paramount. Here are the key features to consider:

By focusing on these quality and safety features, you can ensure that your compressed air piping system operates reliably and safely for years to come.

Proper installation is key to the efficiency of a compressed air piping system. Cleveland Compressed Air Services offers professional installation to ensure your piping layout maximises airflow and minimises pressure loss. Our technicians are trained to handle projects of all sizes, from small workshops to large-scale industrial facilities, guaranteeing a seamless installation process.

Compressed air piping systems are used to transport compressed air from one area to another. An excellent air compressor piping system will help your business become more efficient, therefore resulting in saved time and reduced costs.

An air piping system is simple in theory. After the air has been compressed, filtered and dried, it’s moved through a series of air pipes to deliver the air to its final destination, ensuring minimal pressure loss and a leak-proof operation.

When setting up your compressed air piping system, there are two important considerations to keep in mind:

The Piping Path

Your piping system should connect the compressed air source to its final destination. It should avoid sharp angles, which will slow the airflow and limit its efficiency.

Piping Size & Material

There are various piping materials and sizes to choose from. Your budget, the layout path, the pressure of the compressed air and other factors will help determine the size and materials of the pipes.

Compressed air piping can be made from various materials, though they will largely be plastic or metal. Plastic pipes – such as HDPE pipes – offer the benefit of being cheap and easy to work with and will not corrode as metal pipes do. It’s important to note that there are many types of plastic piping – such as PVC piping – that are not suitable for air compressor lines.

Metal pipes can be made of various materials such as aluminium, galvanised or stainless steel, and copper. Metal pipes have the benefit of great rigidity and are less likely to warp and degrade than plastic pipes are.

Air compressor piping systems are ideal for a variety of industries, including manufacturing, mining companies, construction businesses, food and beverage organisations and more. However, to enjoy the full benefit of your air compressor piping system, it is imperative to choose the right system.

Our team at Cleveland Compressed Air Services has the necessary knowledge and experience to help you choose the best layout, materials and accessories. We also offer access to professional service, repair, maintenance and installation services to ensure that your air piping system is exactly fitted to your needs.

Leaks can severely impact the efficiency of your compressed air piping system. They can be detected through manual inspections, acoustic methods, or using specialised leak detection equipment. Prompt identification and repair are vital for maintaining an efficient, leak-proof system.

Cleveland Compressors has an extensive range of reliable, high-performing machines for industrial applications from some of Australia's leading brands. No matter your industry, Cleveland Compressors is bound to have the right air compressor equipment to suit your individual air demand needs.

If you want to improve your manufacturing and production processes and achieve incredible energy savings, all at a low budget, contact Australia's most reliable industrial solutions provider, Cleveland Compressed Air Services. You can do this by calling (08) 9452 3669, emailing info@ccair.net.au or contacting us online today to address your enquiry!

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.