Enquiry Form

At Cleveland Compressors, we are committed to providing our customers with the highest-quality compressed air solutions and exceptional service. As leaders in the compressed air industry, we ensure that every oil-injected piston air compressor we supply is backed by expert support and the assurance of reliability and efficiency.

We understand the importance of choosing the right equipment for your business needs, and that’s why our team is always on hand to provide guidance, service, and ongoing maintenance to keep your system running smoothly. Whether you need advice on air compressor selection, repairs, or servicing, Cleveland Compressors is here to support you every step of the way.

If you’re unsure which system is right for your operations, contact our expert team on (08) 9452 3669 or email us at info@ccair.net.au.

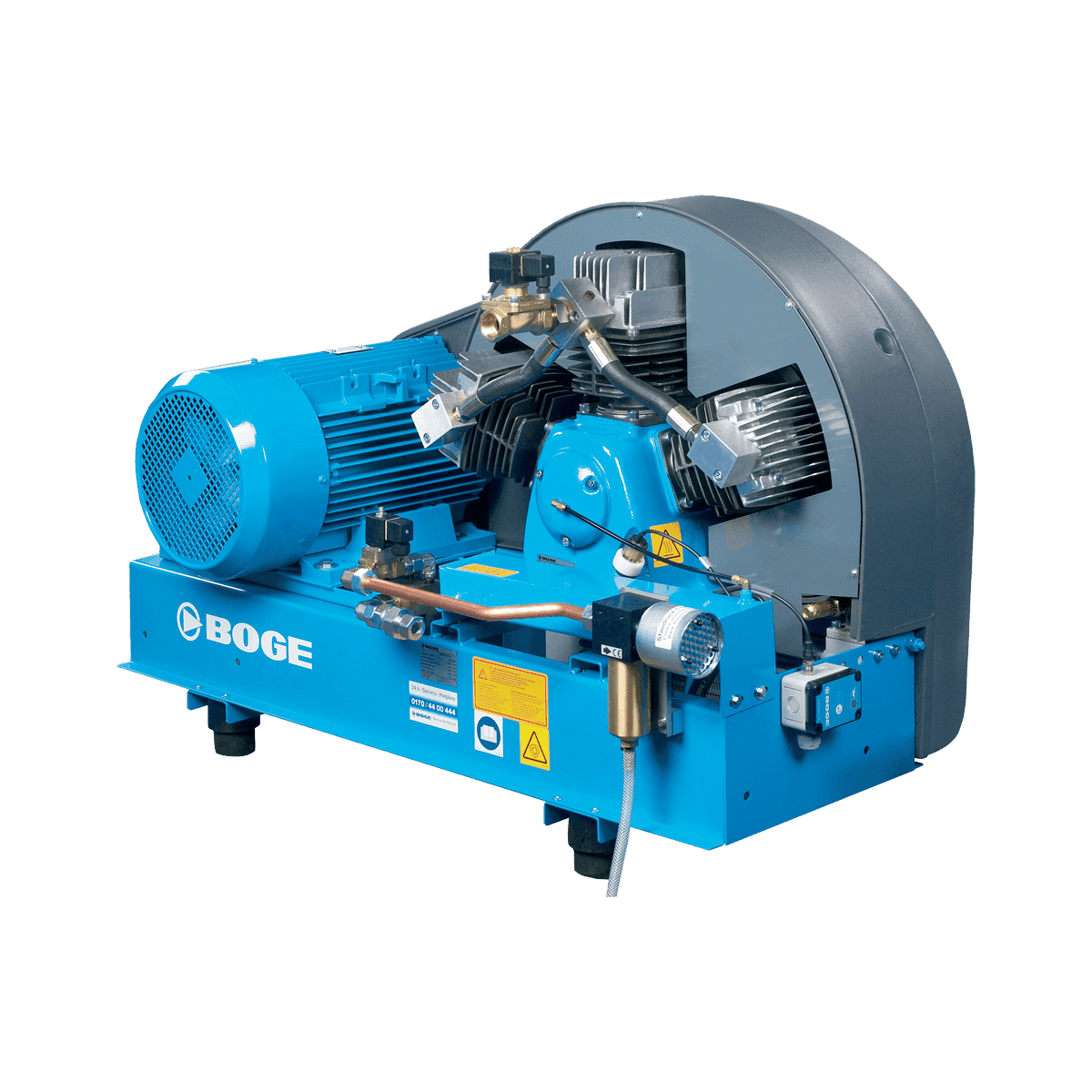

Oil-injected piston compressors use oil lubrication to reduce friction and cool the compression chamber. This increases efficiency, reduces wear on valves and moving parts, and extends the life of your machine.

As the piston moves, air is compressed within the chamber. These robust systems are suited to start-stop operations and are widely trusted in manufacturing, workshops and construction industries.

Oil not only lubricates the internal parts, it also helps cool down the compressed air, minimising heat build-up and improving performance under pressure.

These oil-injected compressors are easier to service than rotary screw models. With regular oil changes, filter replacements, and valve checks, your system will deliver reliable compressed air for years.

Ideal for powering air tools, blowers, tyre inflators, and small machinery, oil-injected piston compressors provide versatile air delivery across a wide range of applications.

An oil-injected piston compressor, also known as a reciprocating compressor, utilises a piston to compress air within a chamber. Oil is injected to lubricate, cool, and reduce wear on internal parts, resulting in efficient and long-lasting performance.

Oil-injected models utilise oil for lubrication, which can lead to trace oil contamination in the compressed air. Oil-free compressors eliminate this risk but tend to be more expensive and less durable in harsh environments. Choose based on your required air quality and end application.

Yes, reciprocating compressors are typically louder than rotary screw or scroll compressors, averaging 70-85 dBA. They're best suited to ventilated areas or separate equipment rooms if noise is a concern.

Oil-injected piston compressors are built for intermittent use. Continuous operation may lead to overheating and excessive wear leading to failure. For 24/7 air demands, we recommend a screw compressor.

Yes. Regular oil changes, air filter checks, and valve servicing are essential for maintaining performance and avoiding breakdowns. Always follow the manufacturer’s guidelines or contact us for a servicing schedule.

Not usually. If air purity is essential (e.g. food, medical, electronics), use oil-free air compressors instead. Oil-injected systems are best for general industrial use where small amounts of oil in the air are acceptable.

Oil-injected piston compressors are widely used in various industries, including:

Note: Compressed air from oil-injected systems should not come into contact with final products in industries requiring high air purity, such as medical or food processing.

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.