Enquiry Form

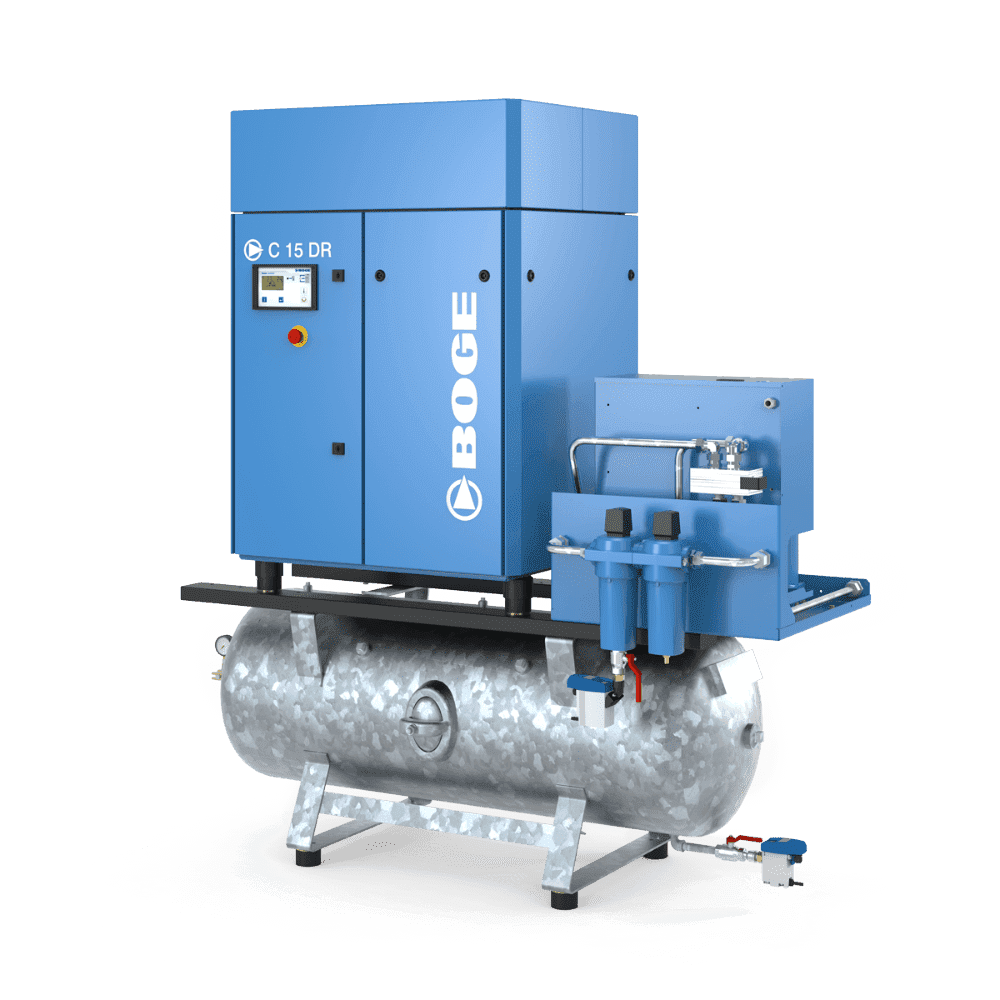

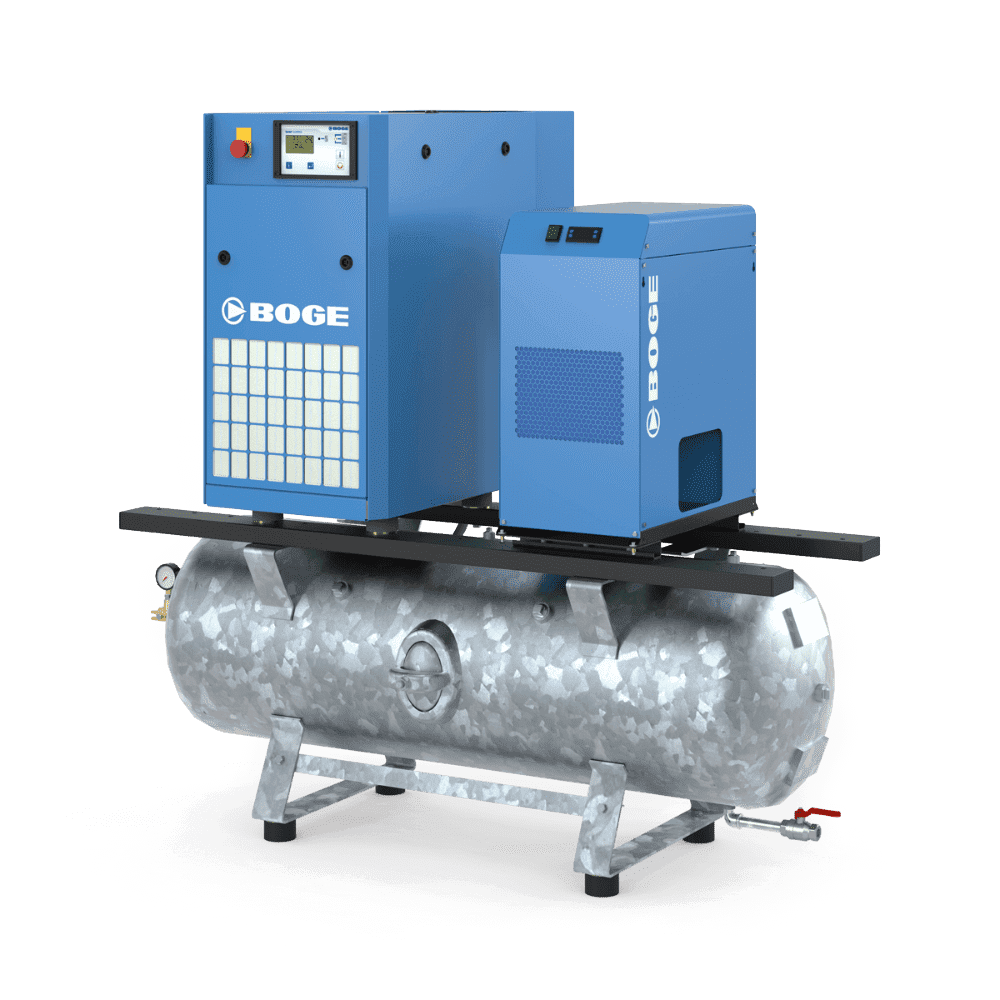

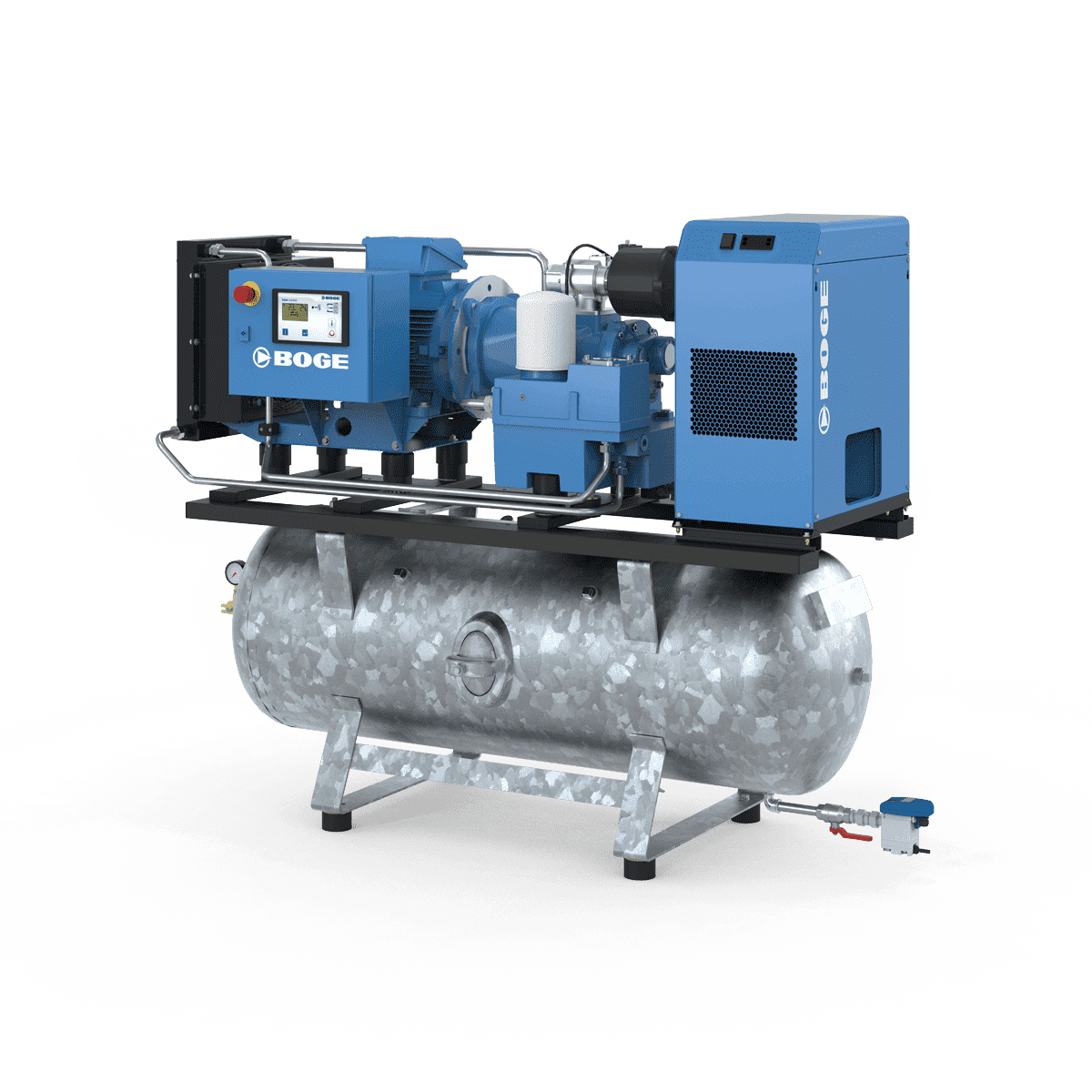

At Cleveland Compressors, we provide high-quality oil-injected screw compressors that are built for continuous use and offer significant energy savings. As industry leaders in the compressed air sector, we ensure that every unit we supply meets the highest standards of reliability, performance, and energy efficiency.

Our experienced team is available to help guide you in selecting the right compressor for your needs, providing ongoing support and maintenance to keep your system running smoothly. Whether you’re looking for advice on energy consumption, performance, or compressor selection, Cleveland Compressors is here to support you every step of the way.

If you’re unsure which system is right for your operations, contact our expert team on (08) 9452 3669 or email us at info@ccair.net.au.

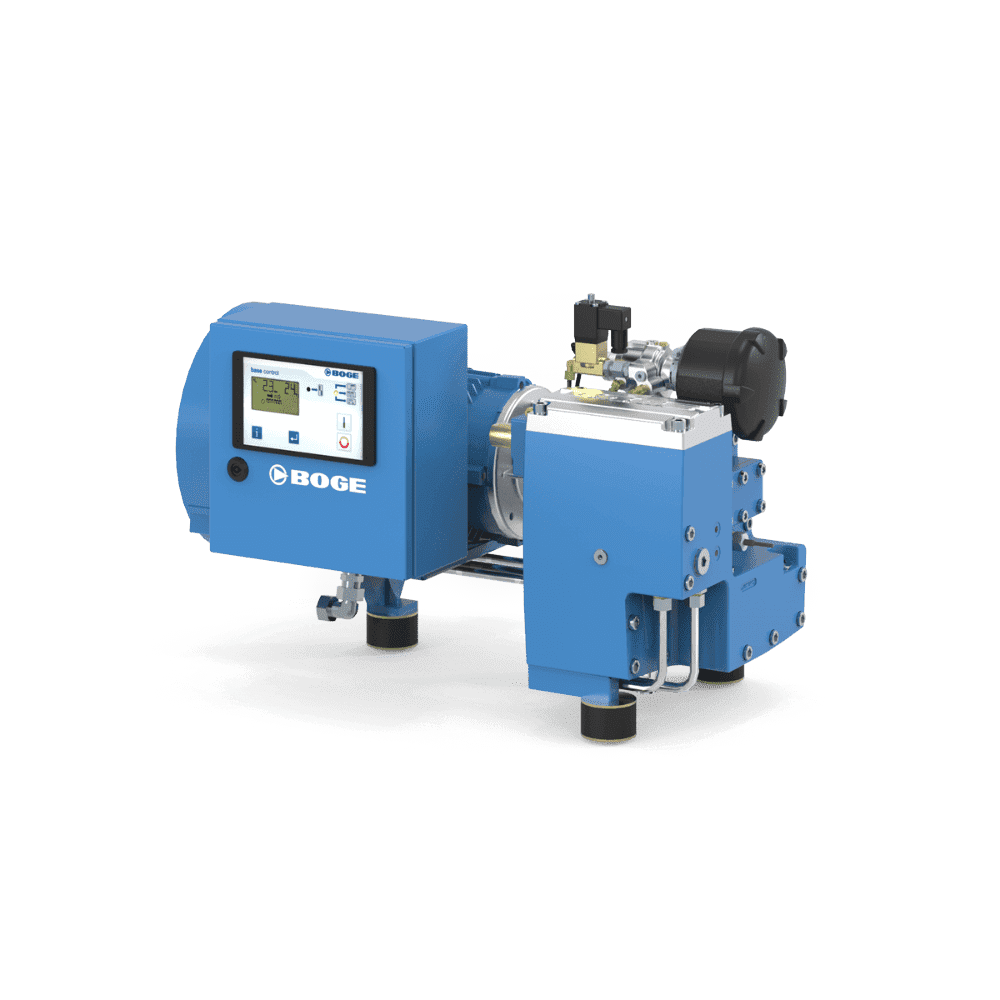

Oil-injected screw compressors use variable speed drive (VSD) technology, which adjusts the motor speed based on demand, leading to energy savings and reduced operational costs. In contrast, fixed speed compressors operate at a constant motor speed and are ideal for applications with steady air demand. VSD compressors help you minimise energy consumption while maintaining consistent performance.

With fewer moving parts and the benefits of oil lubrication, these compressors require less maintenance than other models. Routine maintenance includes oil and oil filter changes and air filter changes, ensuring a long lifecycle and reduced lifecycle costs.

Designed for continuous operation, oil-injected screw compressors deliver reliable, high-volume compressed air around the clock, making them suitable for demanding industrial environments.

Ideal for powering air tools, machinery, and pneumatic systems in various industries, these compressors provide the necessary power and air purity for efficient operations in sectors like automotive, manufacturing, construction, and more.

The oil-lubricated system ensures low wear and tear, resulting in consistent air quality and stable air pressure during continuous use, which is critical for manufacturing processes that require reliable performance.

An oil-injected screw compressor uses oil for lubrication and cooling, allowing the compressor to operate efficiently and continuously. It features interlocking rotary screws that compress the air, delivering high reliability and energy efficiency for industrial applications.

Oil-injected screw compressors offer continuous operation, are energy-efficient with variable speed drive (VSD) technology. They also require less maintenance and have a longer lifespan, making them a cost-effective choice for high-demand applications.

Oil-injected screw compressors with VSD technology adjust the motor speed to meet the actual demand for compressed air, reducing energy consumption during lower demand periods. This minimises energy waste and delivers significant energy savings.

While they are generally quieter than piston compressors, oil-injected screw compressors can still produce noise levels around 65–80 dBA, depending on the model. For quieter operations, soundproofing or placing compressors in separate rooms may be necessary.

Yes, these compressors are specifically designed for continuous use and are ideal for industries that require a constant supply of compressed air. However, routine maintenance, such as oil changes and filter replacement, is required to ensure smooth operation over time.

The size of the compressor depends on your air use and CFM requirements. Cleveland can assist you in selecting the right compressor for your needs, based on the air tools and systems you operate.

Oil changes depend on usage but are typically required every 1,500 to 3,000 hours of operation for mineral based oil and 6,000 to 8,000 hours for synthetic oil. Regular maintenance checks will help determine the optimal oil change schedule for your compressor model.

These compressors are commonly used in industries like:

Oil-injected screw compressors should not be used where oil-free air is critical (e.g. food, pharmaceuticals, medical applications). For these purposes, oil-free screw compressors are recommended to maintain air purity and avoid oil contamination.

If you need further guidance on selecting the right compressor for sensitive applications, feel free to reach out to our team for personalised advice.

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.