Enquiry Form

At Cleveland Compressed Air Services, we pride ourselves on providing our Australian clients with the best products and services in the compressed air industry. We offer customised solutions, high-quality products and a friendly company culture built on core values such as integrity, social responsibility and accountability.

As one of Australia’s leading piston air compressor providers, we recognise the importance of providing high-quality air applications and machinery and professional and timely support. If you’re interested in learning more about our range of piston compressors, please call us today on (08) 9452 3669, email us at info@ccair.net.au or contact us online.

One of the first questions you need to ask when looking to purchase an air compressor is whether you need a piston or a rotary screw compressor. Each compressor is very different in design and is often used for different applications.

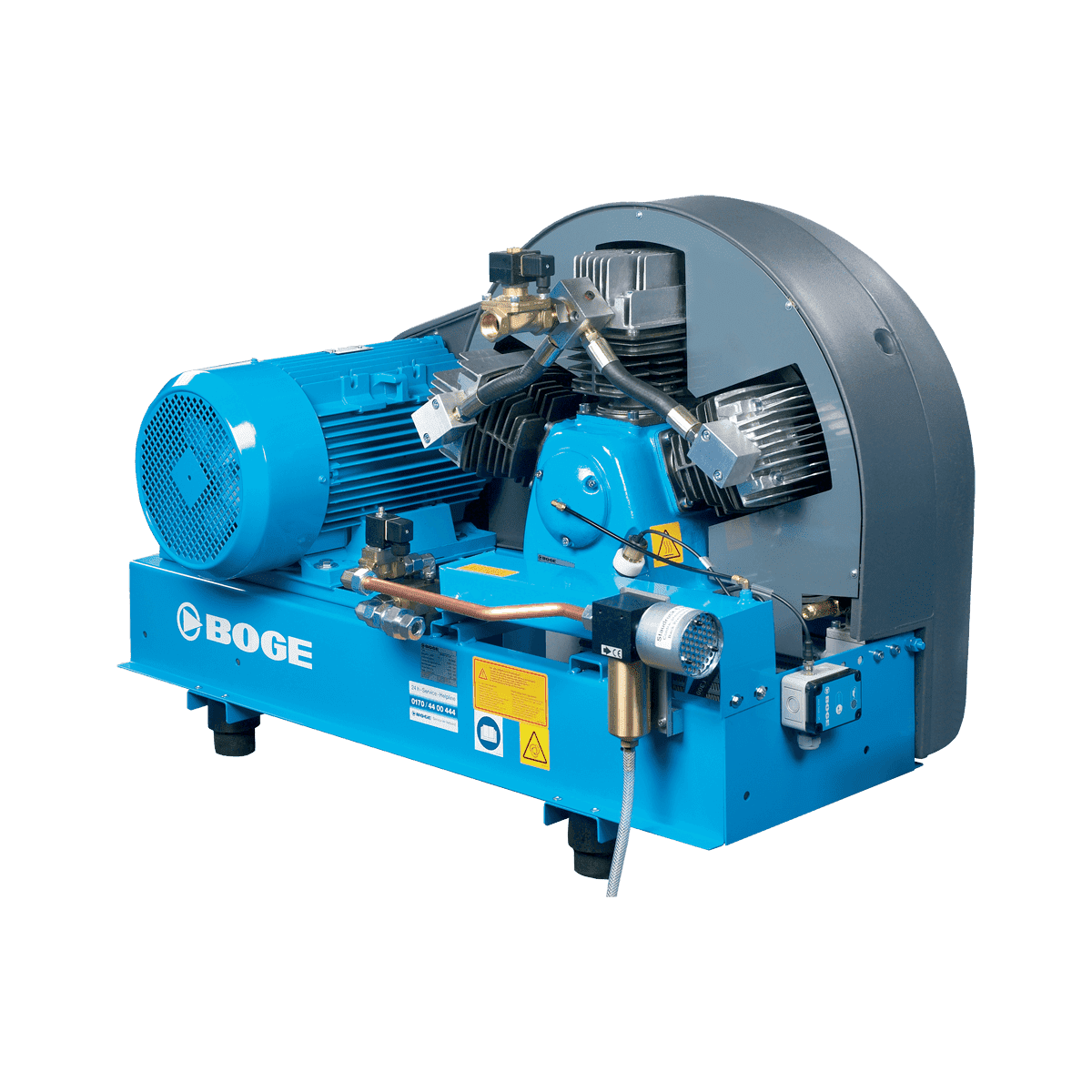

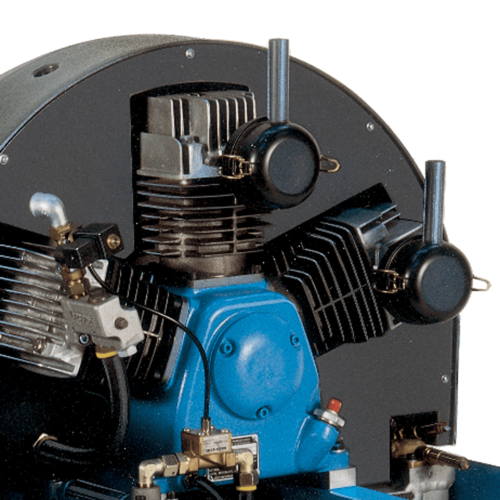

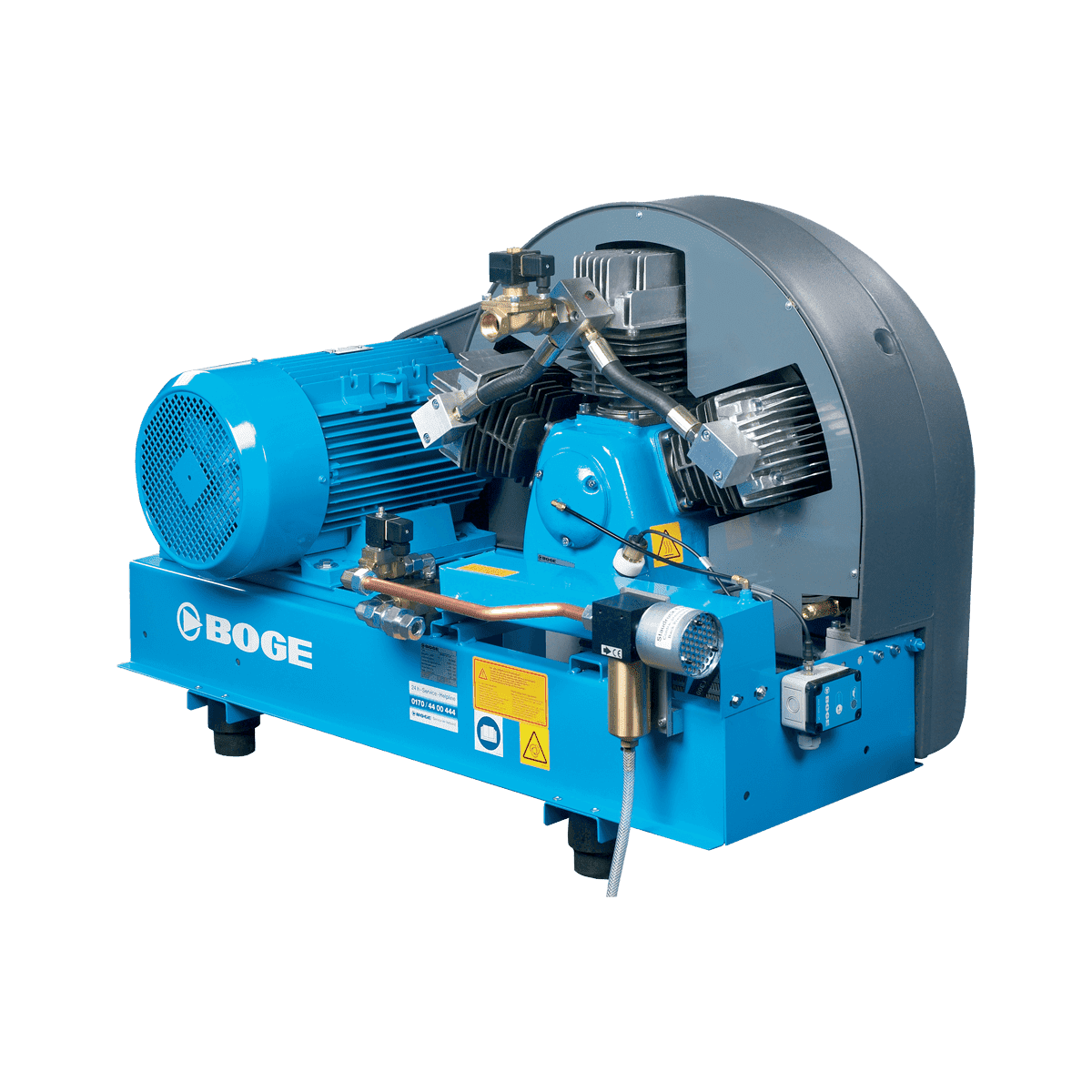

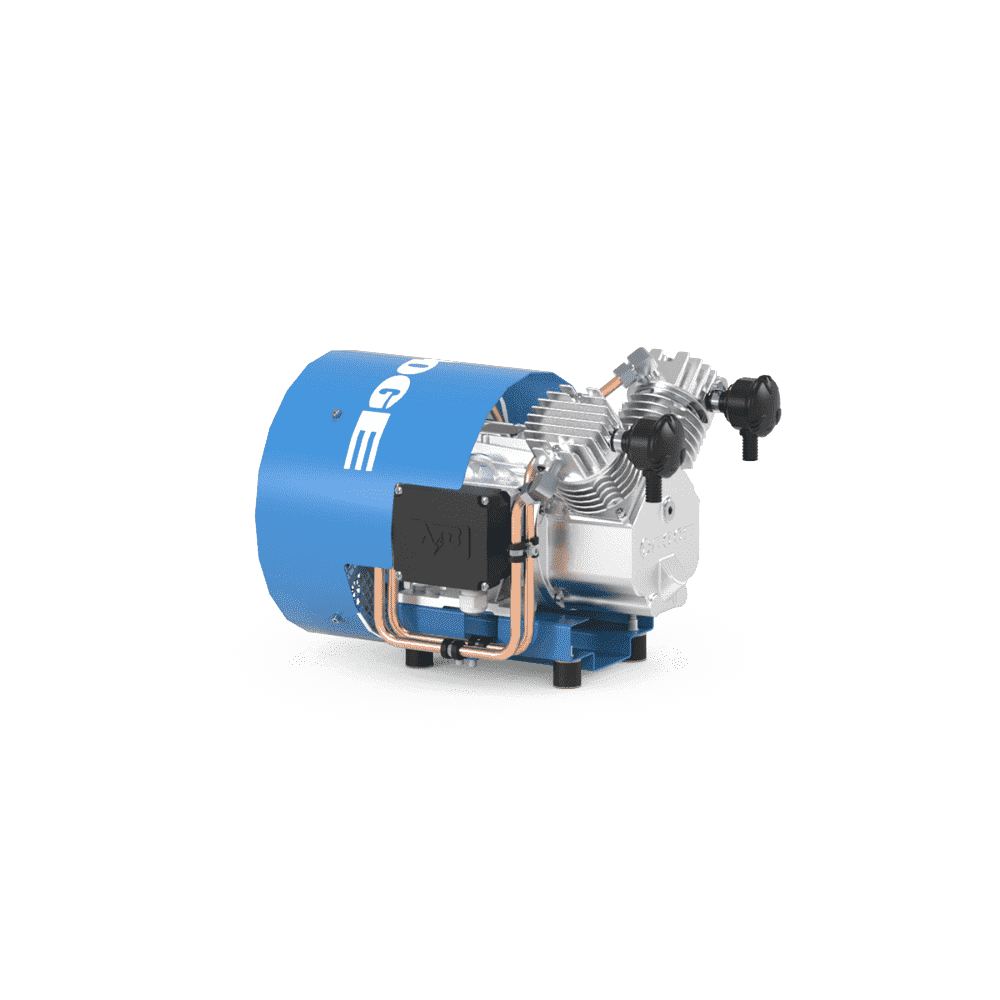

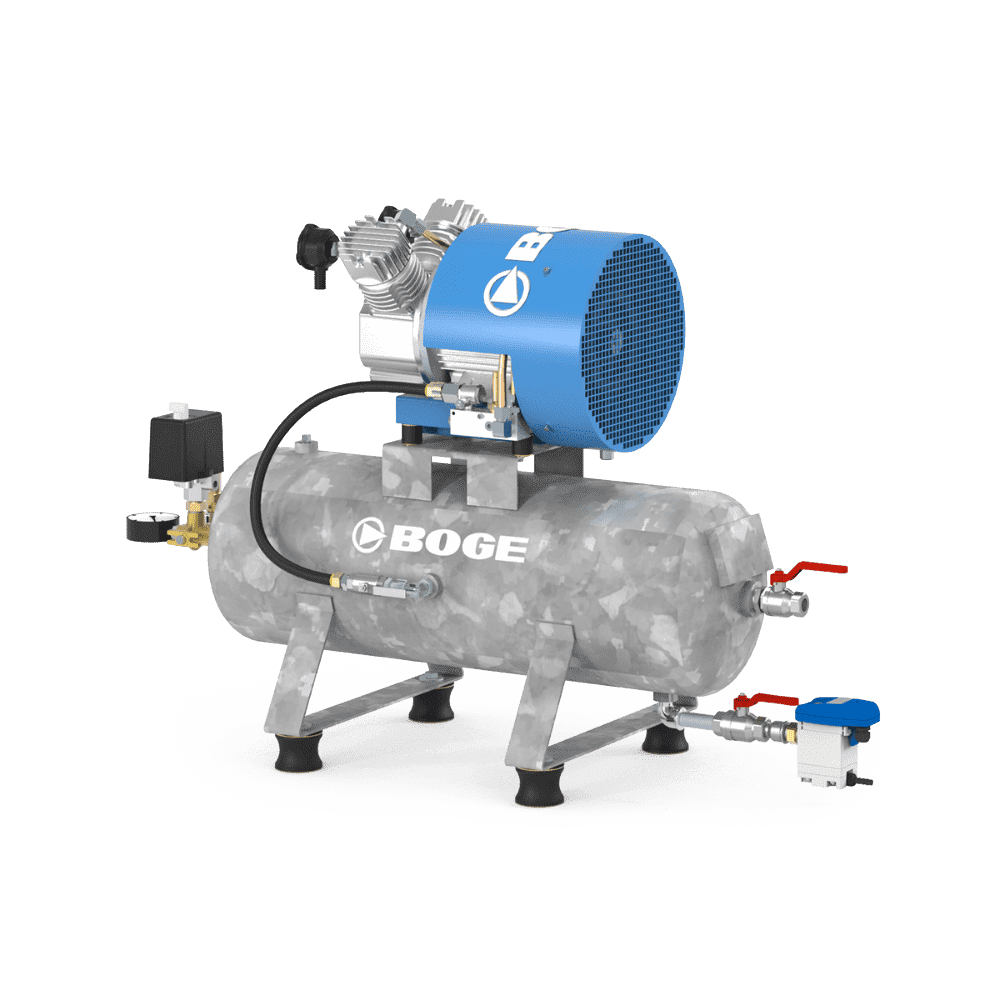

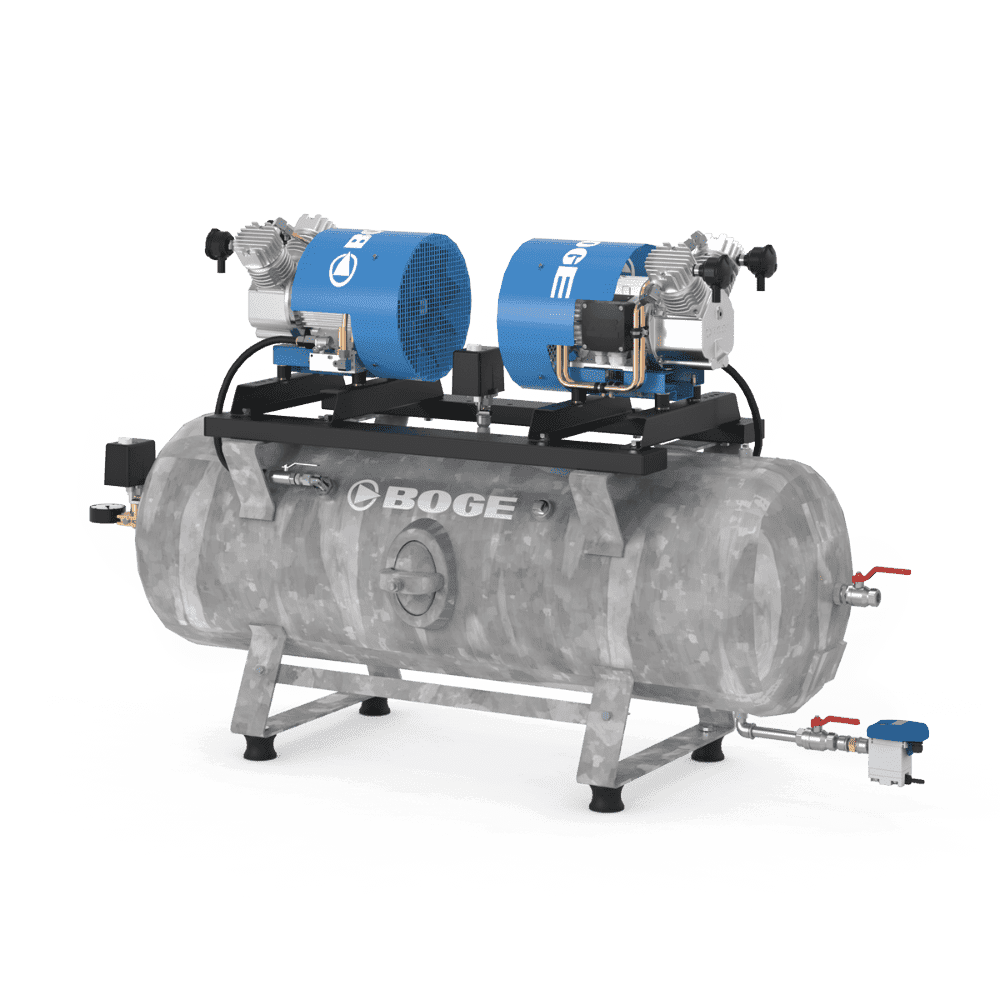

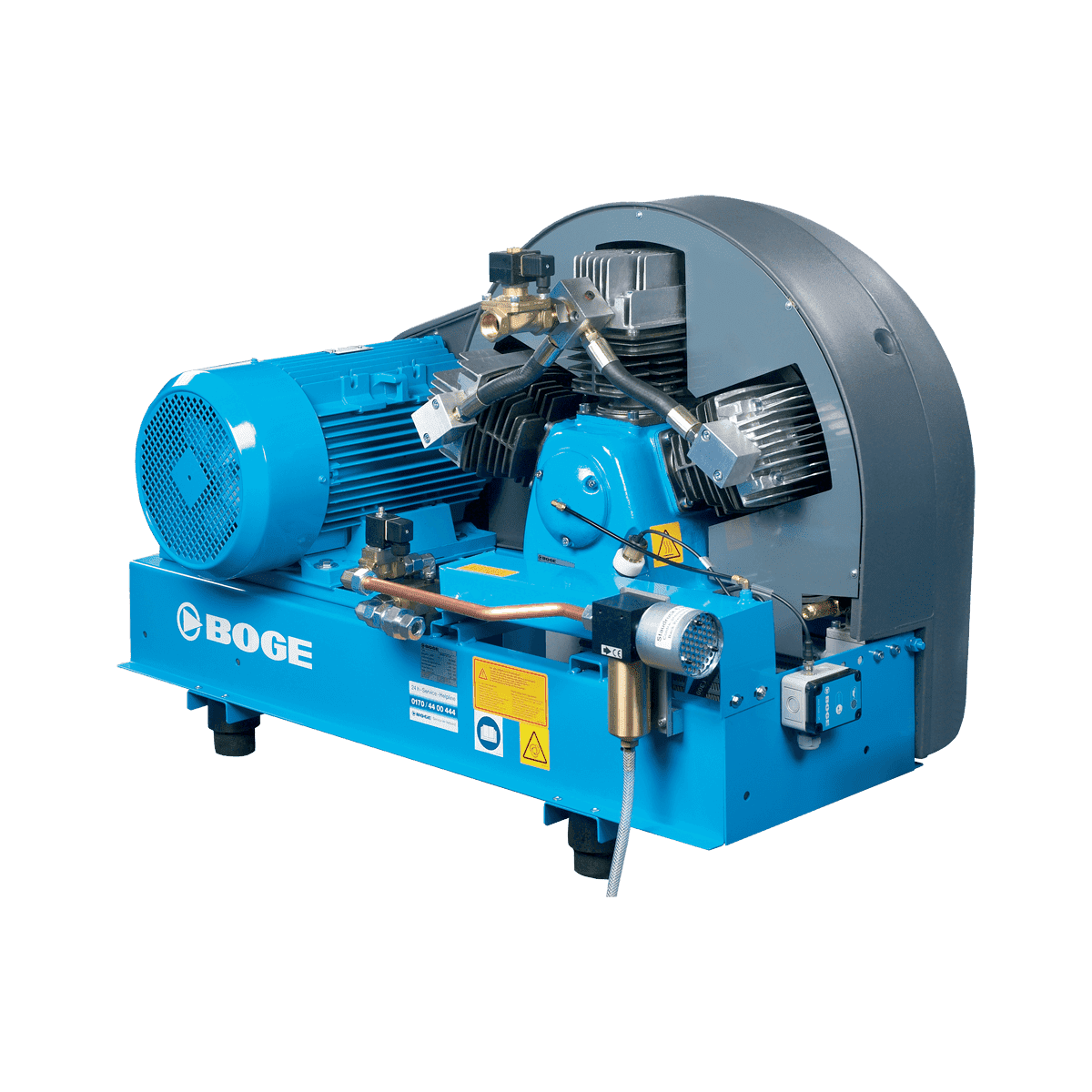

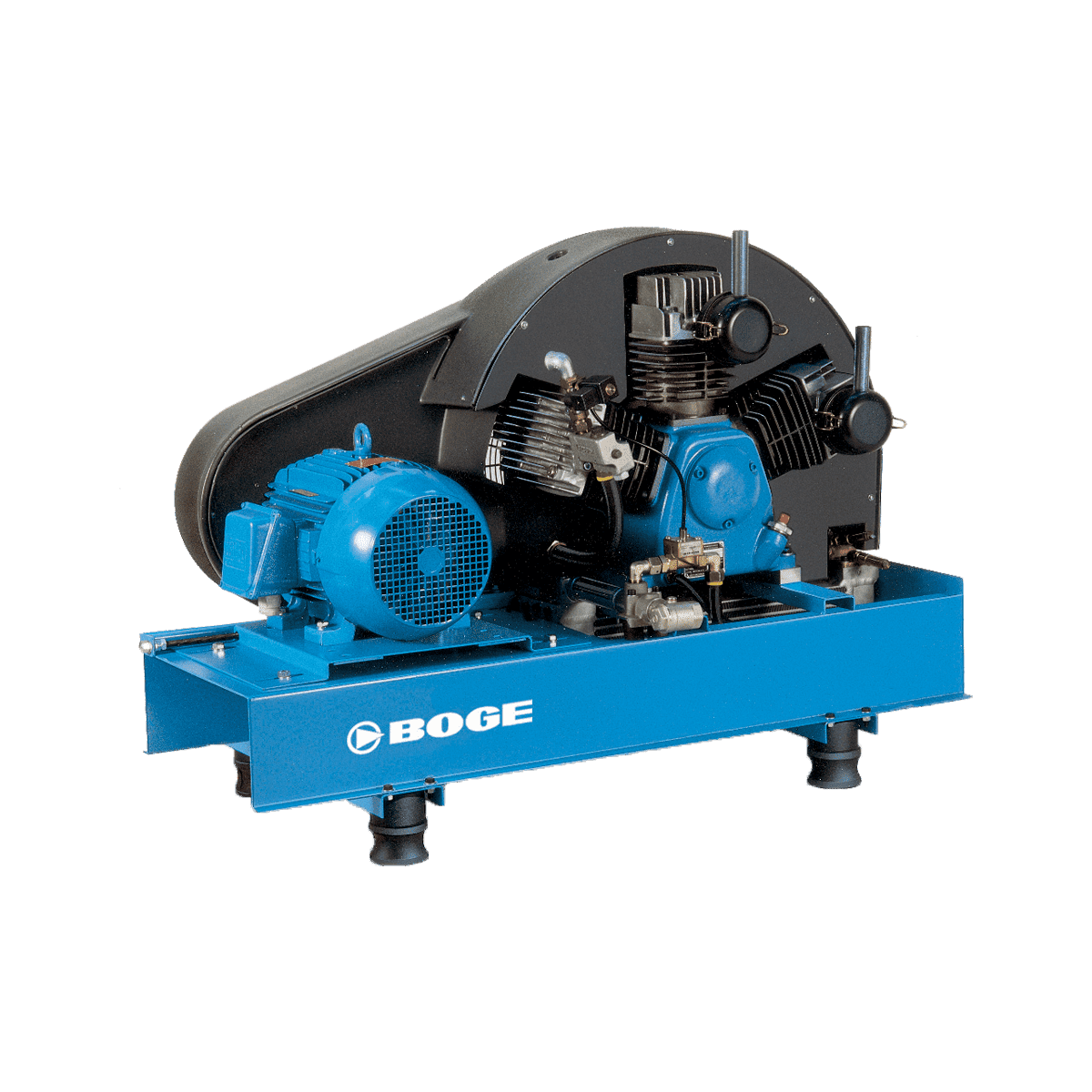

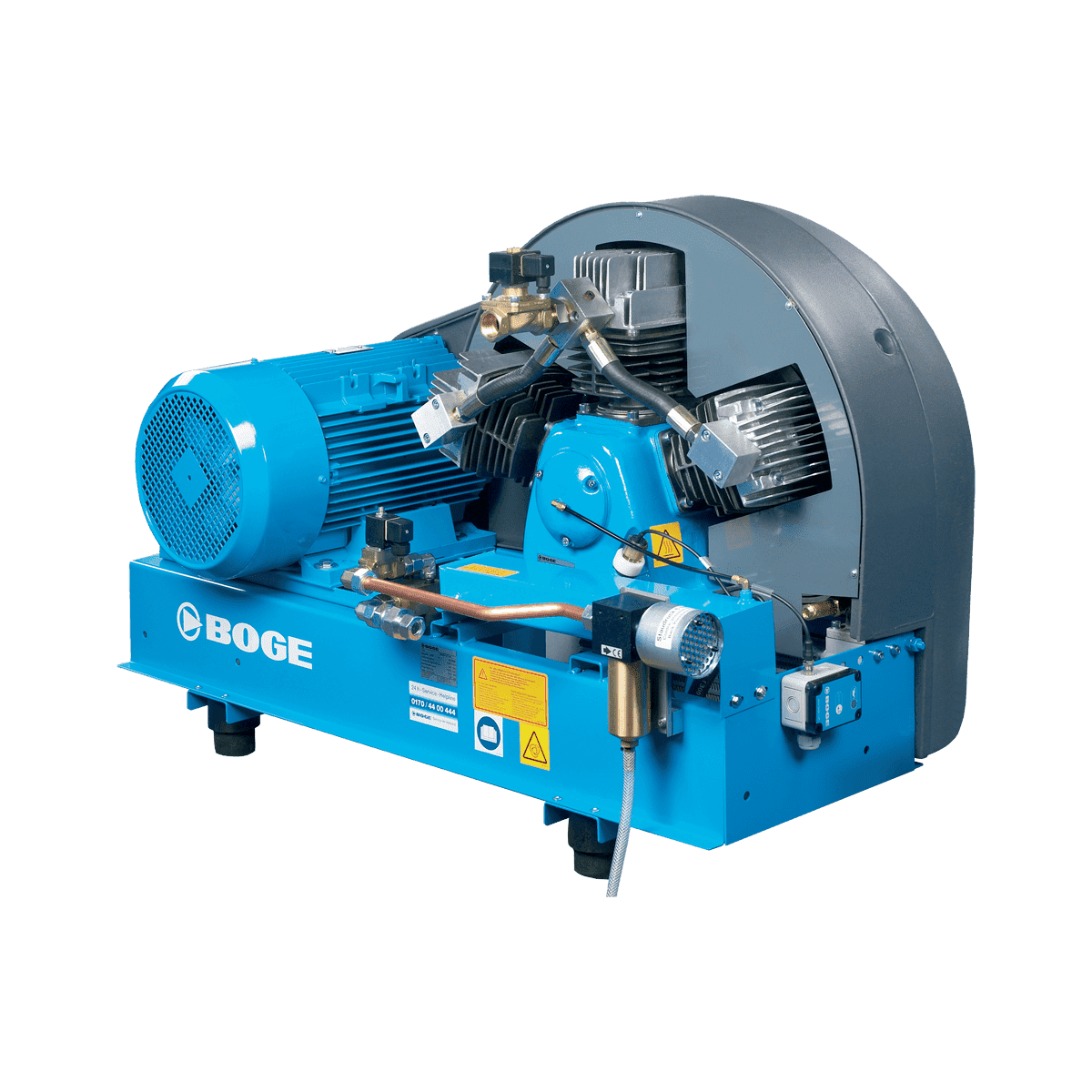

Piston Air Compressor

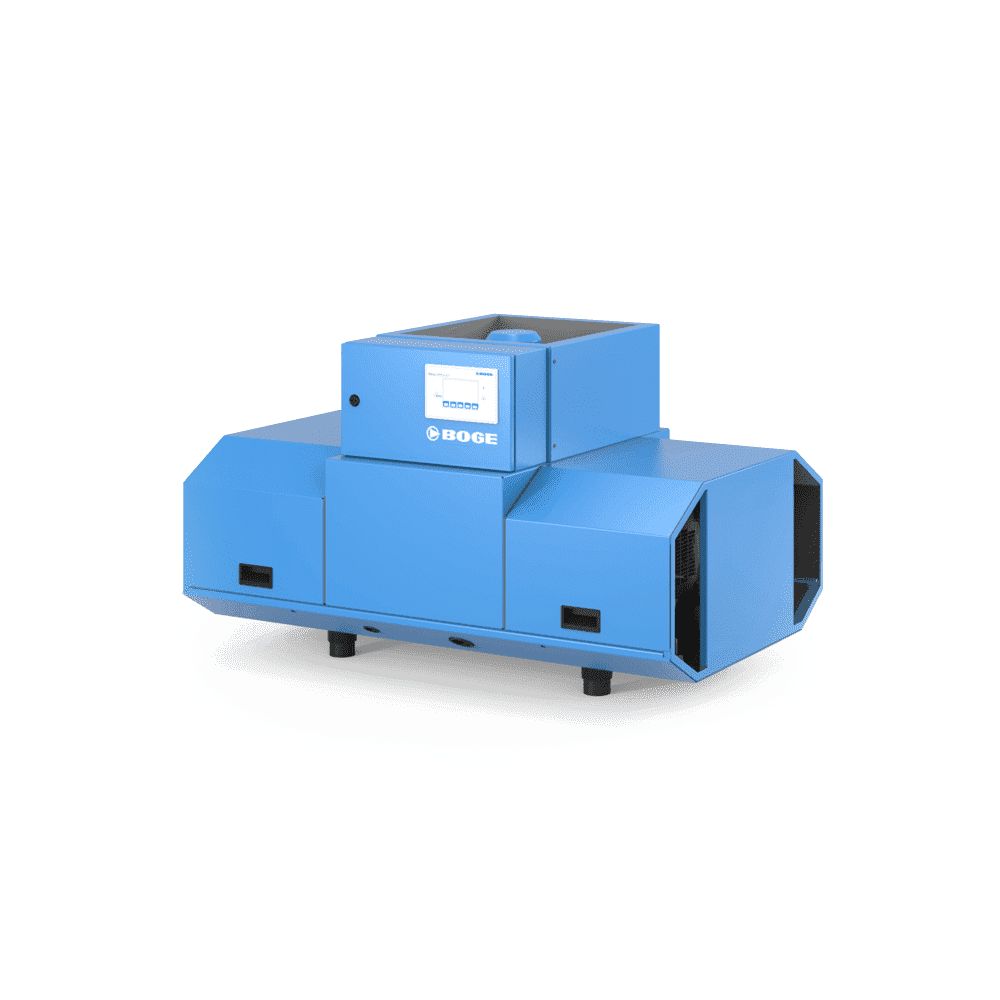

Screw Air Compressor

What size compressor you need is completely dependent on what air-operated equipment you plan on using. To work out what size would be best for you, add up the air usage of all air tools that will be used simultaneously. It’s best to add an extra 20% - 25% to allow for future usage down the track. This is only a rough guide, the best way to ensure you have the correct size machine is to request a compressed air energy audit.

No, they do not. It’s always best to check for any problems after the first start-up but after that, you are ready to go. If you do find any leaks or problems, turn the machine off and be sure to contact your product provider before operating any air compressor equipment again.

Many air compressors are able to run off generators, however, it is not recommended. If you have access to mains electricity, it is recommended you use that to power your air compressor equipment. Generators have fluctuations in power which can cause problems for compressors as they require a constant voltage to run. It is even more important for rotary screw compressors to be run off mains electricity rather than generators due to their constant operation.

If you are only using your machine occasionally then annually servicing your compressed air equipment should be sufficient. If you are operating your air compressor routinely, then it may be best to service it quarterly. It is always recommended to do small services whenever you have the ability and time to.

If you are ever worried that your air compressor is not working the way it is intended, it is always safest to turn it off and have a trained industry professional come and inspect its components.

When looking to improve energy efficiency, customers have to look further than the air compressor and evaluate the compressed air system as a whole. The most essential part for improvement is generally your air piping system — how the compressed air is transported and used in the end application. Both the design of the distribution and the material used for piping affect energy efficiency. Consult with a compressed air specialist to see what steps can be taken to pursue reduce your energy cost. By running an energy-efficient operation, your business works toward saving money and creating a more sustainable future.

Cleveland Compressors have an extensive range of reliable, high-performing machines for industrial applications from some of Australia's leading brands. No matter your industry, Cleveland Compressors is bound to have the right air compressor equipment to suit your individual air demand needs. If you want to improve your manufacturing and production processes and incredible energy savings, all at the lowest cost, contact Australia's most reliable industrial solutions provider, Cleveland Compressed Air Services by calling (08) 9452 3669, emailing info@ccair.net.au or contacting us online today!

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.