Enquiry Form

At Cleveland Compressed Air Services, we pride ourselves on providing our Australian clients with the best products and services in the compressed air industry. We offer customised solutions, high-quality products and a friendly company culture built on core values such as integrity, social responsibility and accountability.

As one of Australia’s leading oil-free air compressor providers, we recognise the importance of providing high-quality air applications and machinery and professional and timely support. If you’re interested in learning more about our range of oil-free compressors, please call us today on (08) 9452 3669, email us at info@ccair.net.au or contact us online.

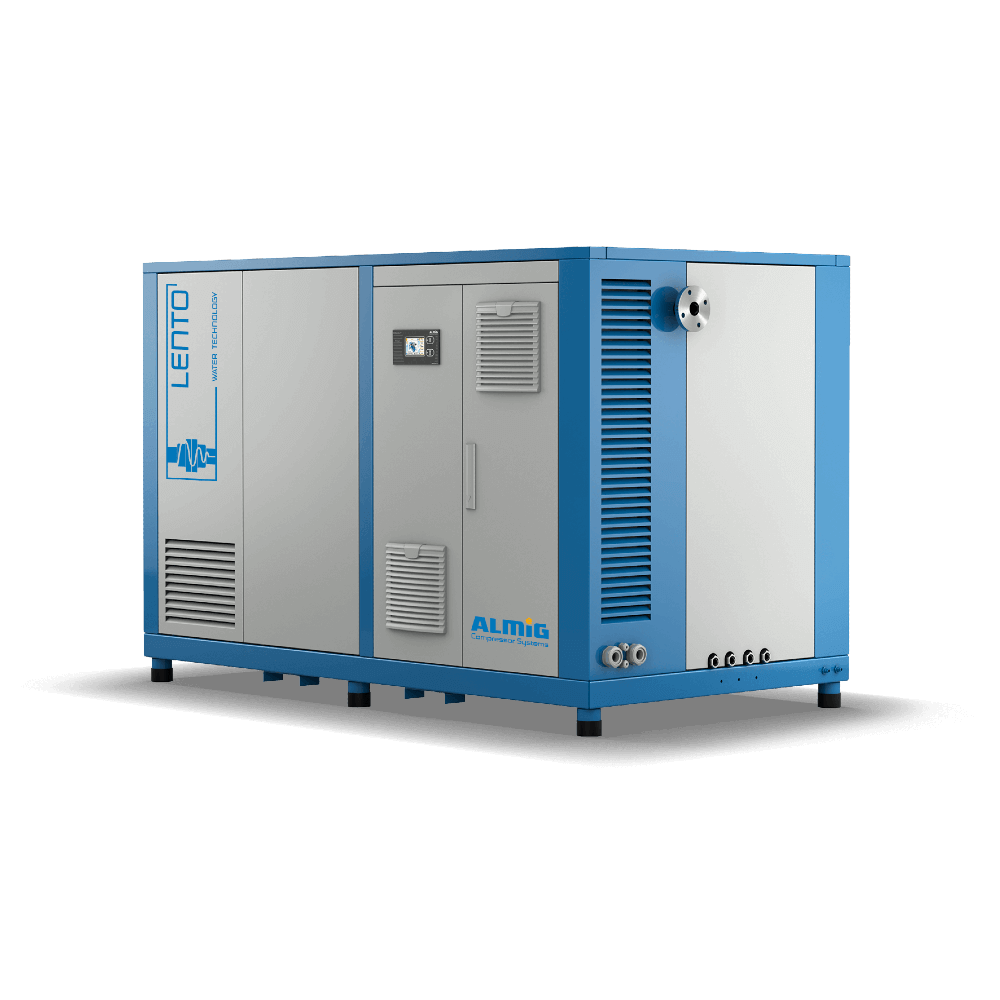

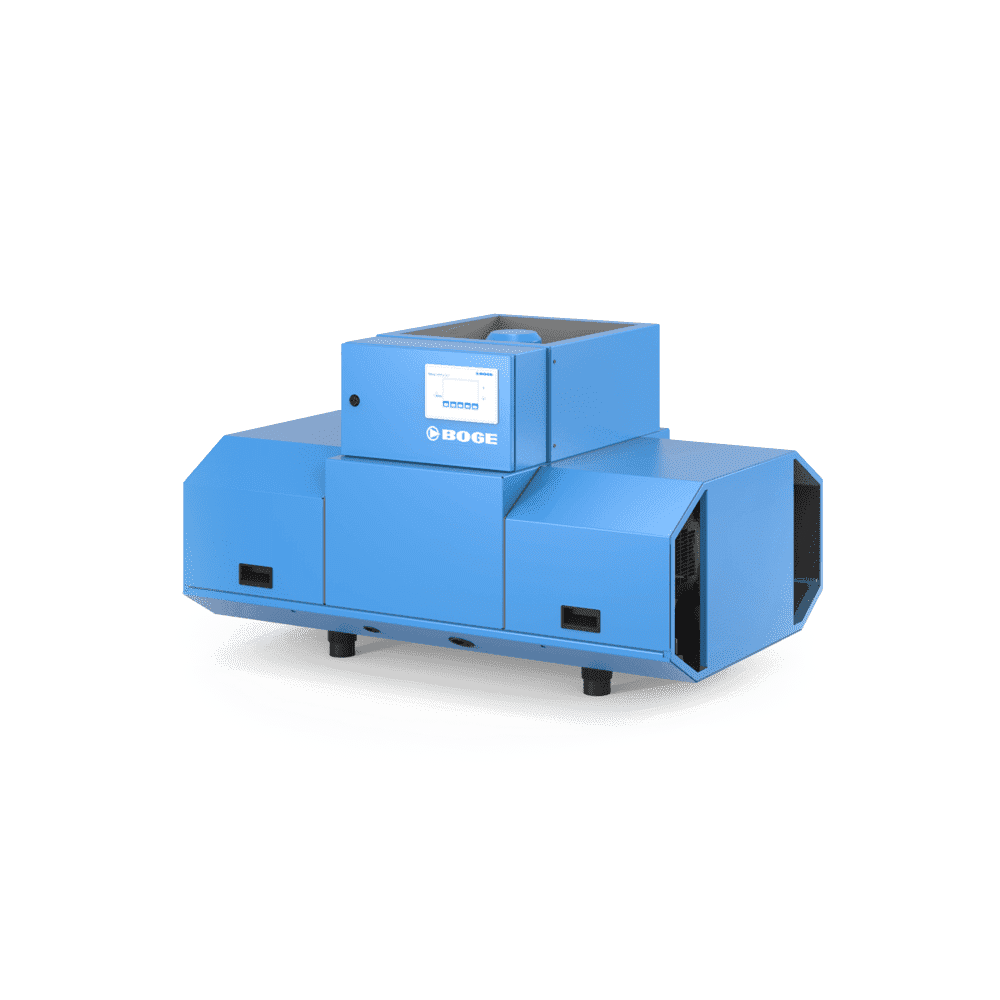

Oil-free compressors are designed for environments where even the smallest traces of oil are unacceptable, such as in food production. While they may have a higher initial cost and a shorter lifespan compared to oil-lubricated compressors, they provide a clean, contamination-free solution for sensitive applications. If maintaining air purity is a top priority, an oil-free compressor is the ideal choice. Here are a few key factors to consider when selecting the right air compressor for your needs.

Oil-Injected Air Compressor

Oil-Free Air Compressor

No, they do not. It’s always best to check for any problems after the first start-up but after that, you are ready to go. If you do find any leaks or problems, turn the machine off and be sure to contact your product provider before operating any air compressor equipment again.

Many air compressors are able to run off generators, however, it is not recommended. If you have access to mains electricity, it is recommended you use that to power your air compressor equipment. Generators have fluctuations in power which can cause problems for compressors as they require a constant voltage to run. It is even more important for rotary screw compressors to be run off mains electricity rather than generators due to their constant operation.

If you are only using your machine occasionally, then an annual service of your compressed air equipment should be sufficient. If you are operating your air compressor routinely, then it may be best to service it quarterly. It is always recommended to do small services whenever you have the ability and time to.

If you are ever worried that your air compressor is not working the way it is intended, it is always safest to turn the unit off and have trained service technicians come and inspect the components of your compressed air system.

When looking to improve energy efficiency, customers have to look further than the air compressor and evaluate the compressed air system as a whole. The most essential part for improvement is generally your air piping system — how the compressed air is transported and used in the end application. Both the design of the distribution and the material used for piping affect energy efficiency. Consult with a compressed air specialist to see what steps can be taken to pursue reduce your energy cost. By running an energy-efficient operation, your business works toward saving money and creating a more sustainable future.

The working pressure of oil-free air compressors varies depending on the model and application. Generally, they operate within a range of 90 to 145 psi, which is sufficient for most industrial applications. It’s important to choose a model with the appropriate working pressure to optimise your system’s efficiency and performance.

The sound level of the air compressors depends on the technology. Oil-free scroll compressors are one of the quietest air compressors around. The screw compressors are otherwise at a similar noise level, whether oil-injected or oil-free.

To optimise the efficiency of your compressed air system, it’s important to regularly review and maintain all components, including the air compressor, piping, and filtration systems. Ensuring that your system is properly engineered and designed specifically for your application can reduce energy costs and enhance overall performance. Consulting with a professional who understands the critical aspects of compressed air systems can help you achieve the best results.

Oil-free air compressors are designed specifically to provide 100% clean air, making them the best choice for sensitive applications such as in the medical, dental, food, and beverage industries. These compressors eliminate the risk of oil contamination, which is critical in maintaining the quality and safety of your products. Additionally, oil-free compressors are engineered to deliver reliable performance with lower maintenance costs compared to oil-injected models, though they may have a shorter lifespan. Investing in an oil-free air compressor is ideal for sectors where air quality cannot be compromised.

Investing in an oil-free air compressor is ideal for industries where air purity is critical, such as food processing, pharmaceuticals, and electronics. These air compressors provide clean, contaminant-free air, reducing the risk of product defects and ensuring compliance with stringent quality and safety standards. Choosing an oil-free solution contributes to sustainability goals and enhances a facility's environmental profile. Additionally, oil-free air compressors create less waste by reducing the need for oil and minimising disposables required after maintenance.

Oil-free air compressors come with various professional features that enhance their reliability and performance. These compressors are also equipped with technology that ensures compliance with ISO Class 0 air quality standards, making them suitable for the most demanding applications. Additionally, oil-free air compressors are ideal for critical applications, ensuring reliable and contaminant-free air in demanding industries.

At Cleveland Compressed Air Services, we offer comprehensive support for our oil-free air compressor range. Our services include installation, service, maintenance, and repairs to ensure your compressor operates at peak efficiency. We understand the importance of reliability in your operations, which is why our products and services are designed to meet the highest standards. Whether you’re looking for a new system or need support with your existing setup, our team is here to help.

Oil-free compressors generally require more frequent maintenance compared to oil-injected models. While they eliminate the need for oil changes, components such as filters, seals, and air dryers must be checked and replaced regularly to maintain efficiency. The exact maintenance schedule depends on usage, but routine servicing is recommended every 1,500 to 4,000 hours of operation, depending on model and environment.

While oil-free air compressors reduce the risk of oil-related contamination and maintenance issues, they may have a shorter lifespan due to increased wear on components. Proper maintenance, including regular filter changes and moisture management, is key to maximising their longevity.

Cleveland Compressors has an extensive range of reliable, high-performing machines for industrial applications from some of Australia's leading brands. No matter your industry, Cleveland Compressors is bound to have the right air compressor equipment to suit your individual air demand needs.

If you want to improve your manufacturing and production processes and achieve incredible energy savings, all at a low budget, contact Australia's most reliable industrial solutions provider, Cleveland Compressed Air Services. You can do this by calling (08) 9452 3669, emailing info@ccair.net.au or contacting us online today to address your enquiry!

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.