Enquiry Form

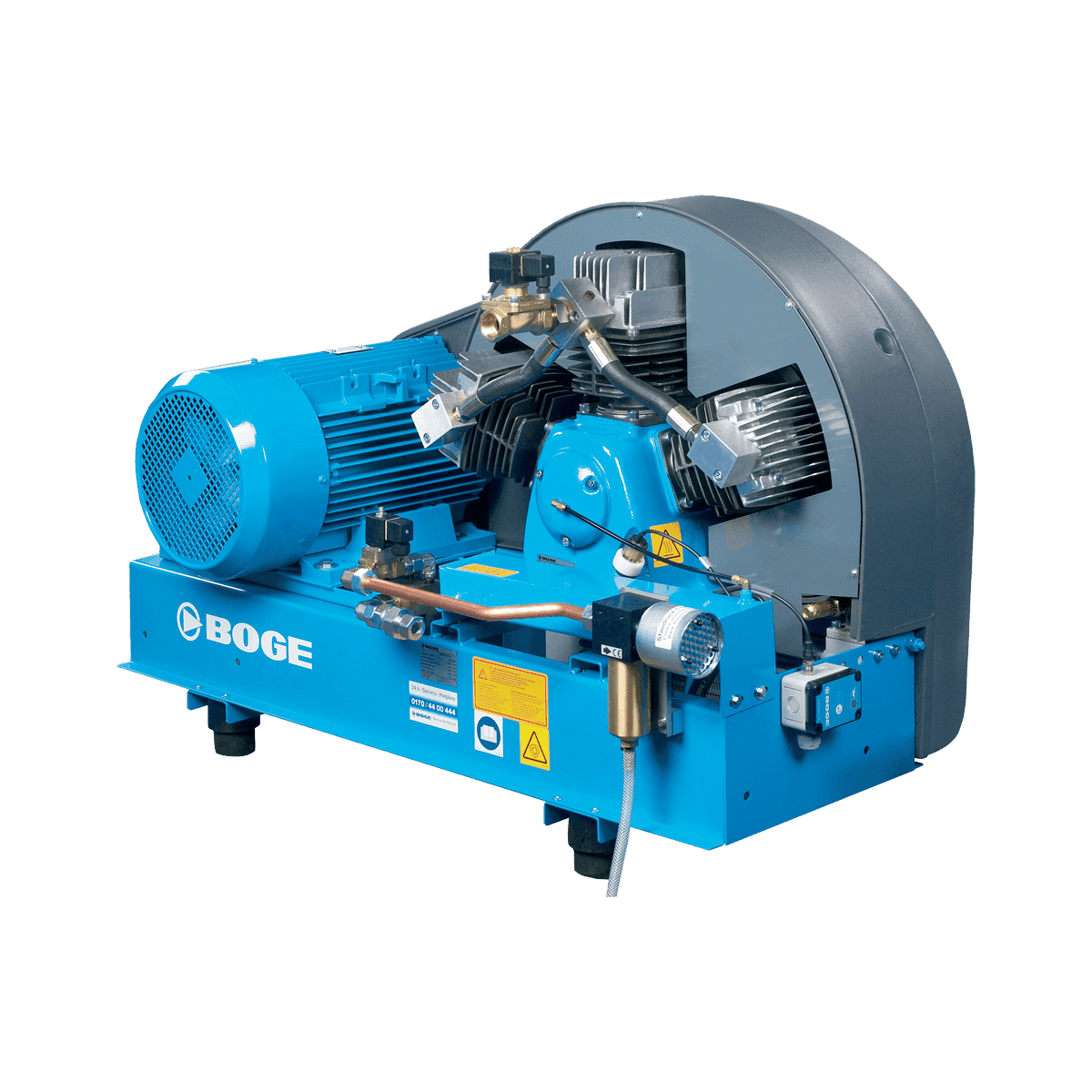

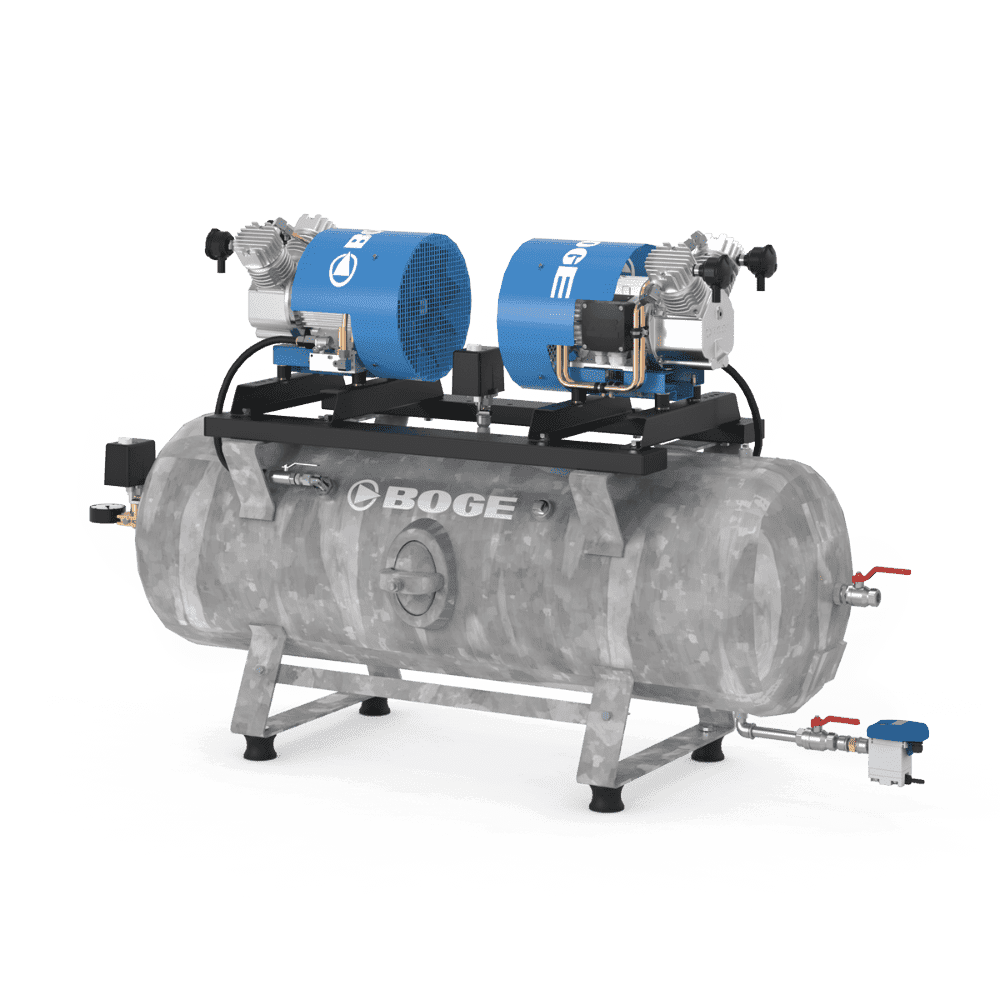

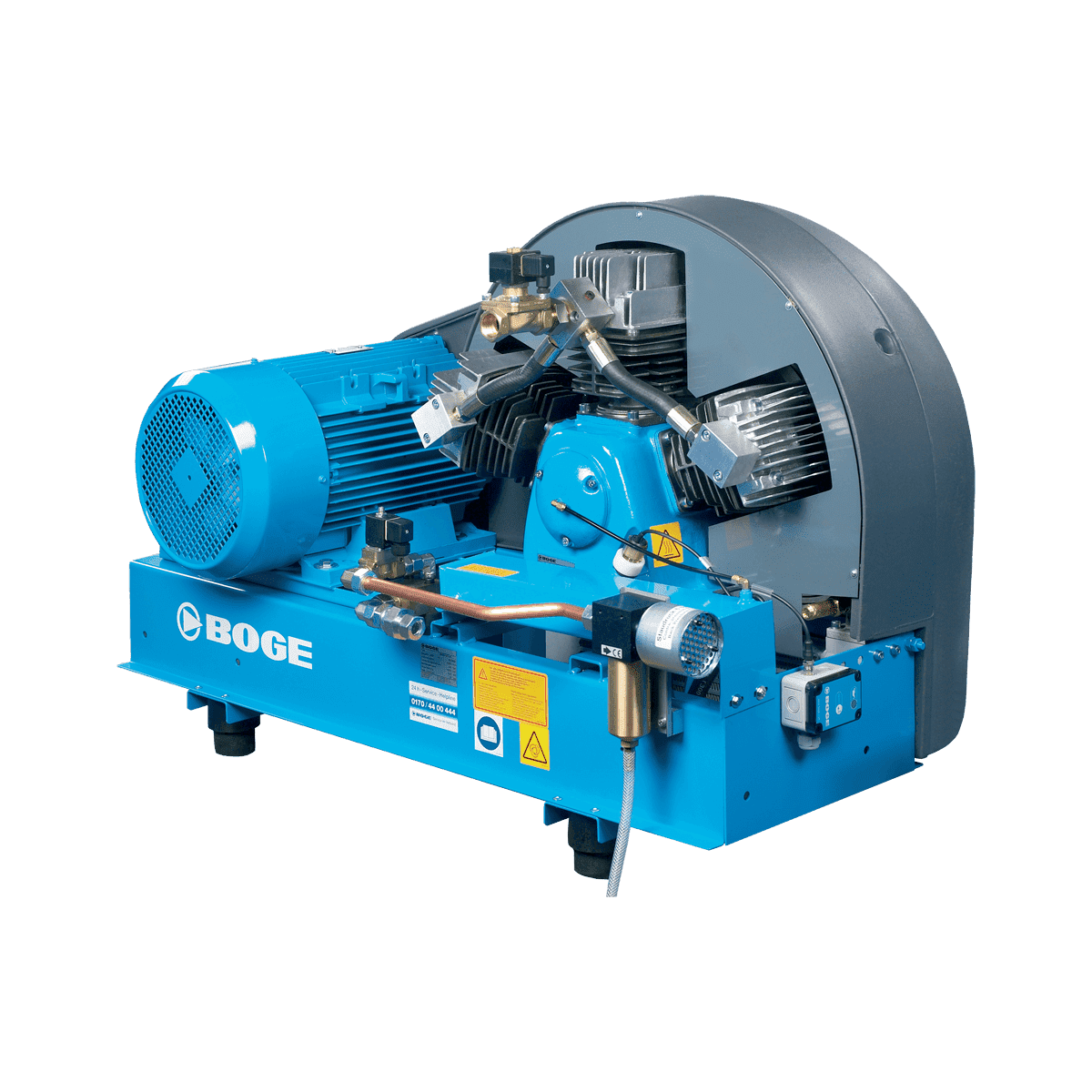

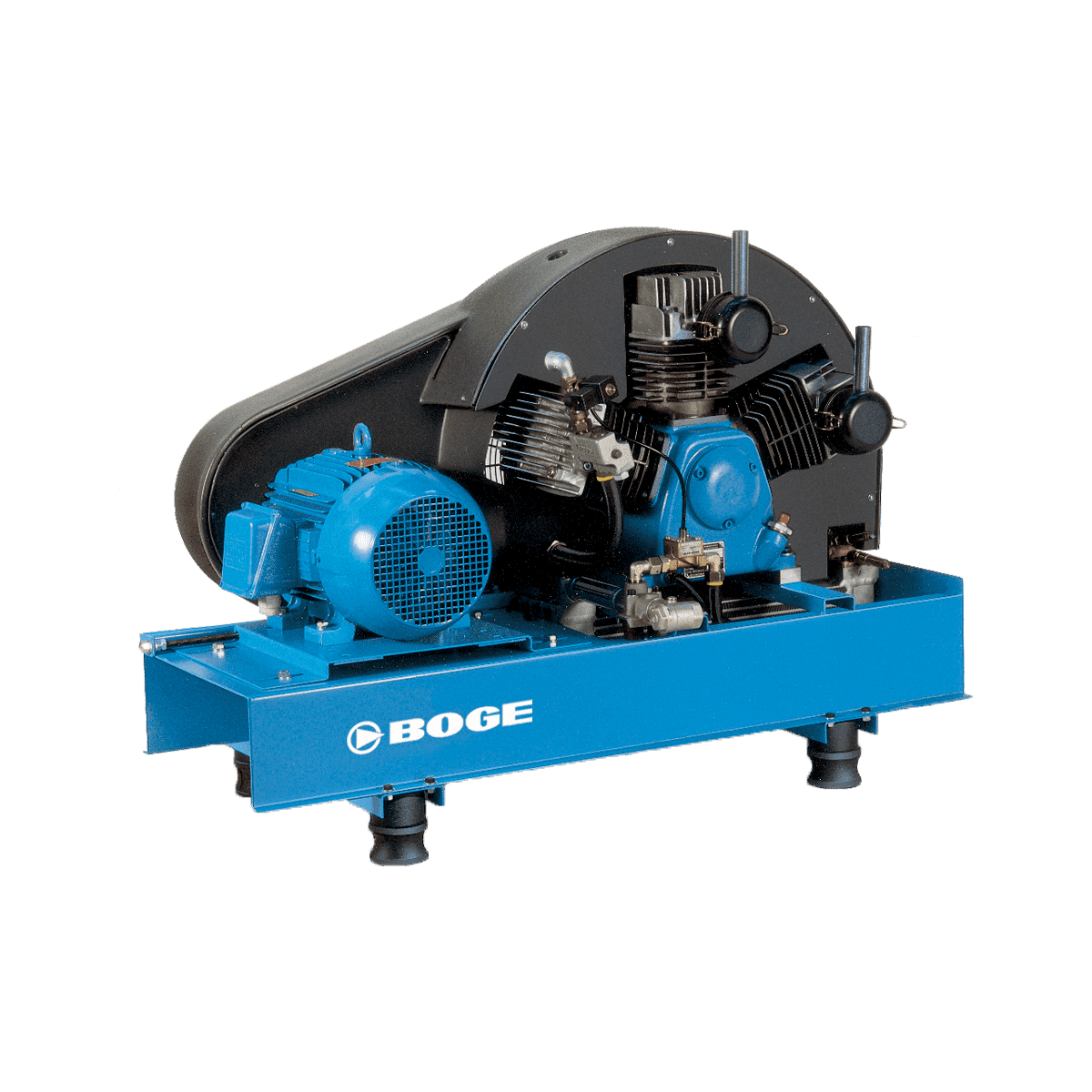

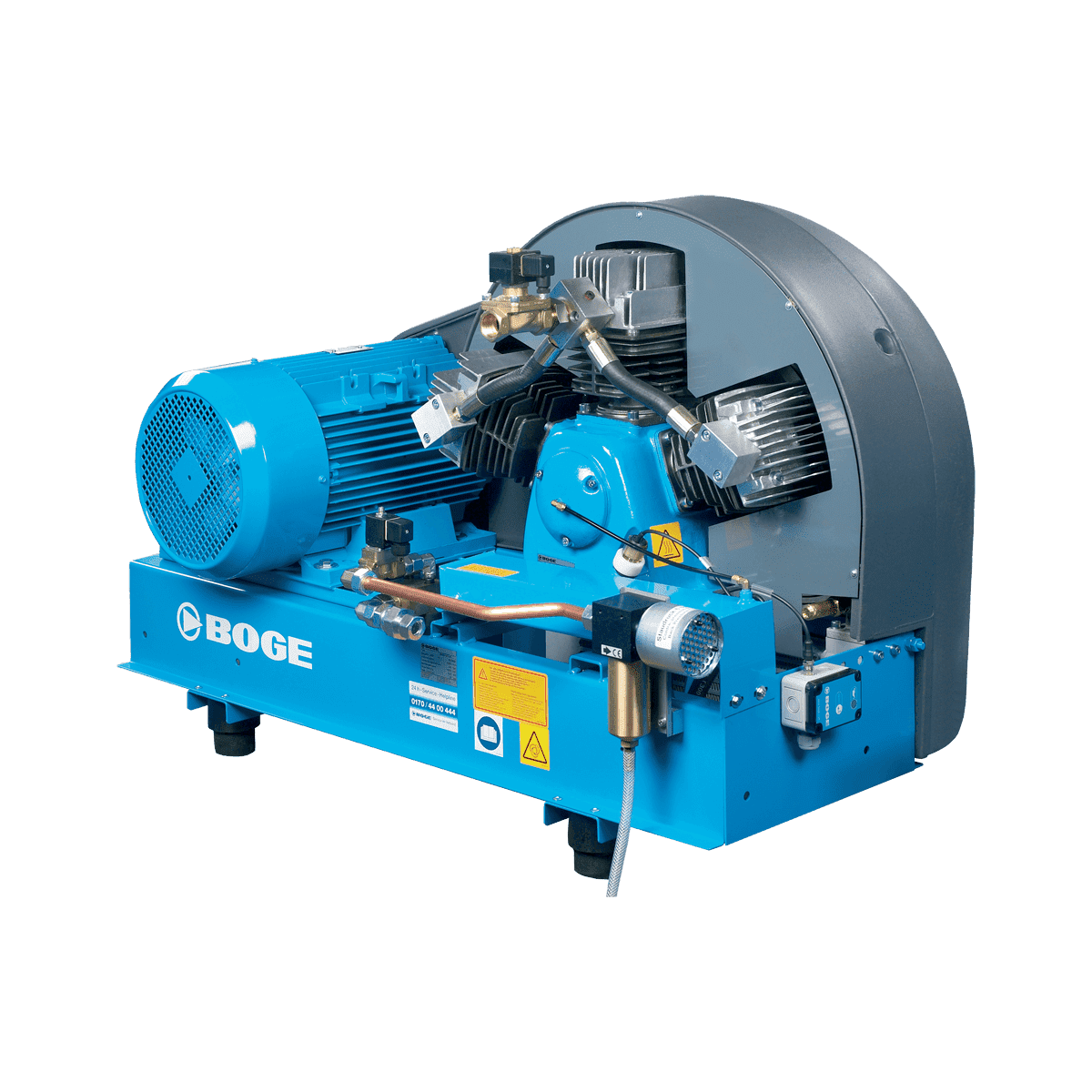

At Cleveland Compressors, we offer top-quality piston compressors in both oil-lubricated and oil-free configurations, catering to a wide range of industries. Whether you need oil-lubricated durability for heavy-duty applications or oil-free air for sensitive processes, we ensure each piston compressor meets the highest standards of performance, efficiency, and reliability.

Our expert team is available to guide you in selecting the right reciprocating air compressors for your operations. Whether it’s about energy consumption, performance, or maintenance schedules, Cleveland Compressors is here to support you at every step.

If you’re unsure which system is right for your operations, contact our expert team on (08) 9452 3669 or email us at info@ccair.net.au.

We offer both oil-lubricated piston compressors and oil-free piston compressors, giving you flexibility based on your specific air quality requirements. Oil-lubricated models excel in heavy-duty applications, providing extended durability and low maintenance, while oil-free piston compressors are ideal for applications where pure, oil-free air is essential, such as in food processing, water treatment or medical applications.

Both oil-lubricated and oil-free piston compressors provide excellent energy efficiency. Oil-lubricated piston compressors typically feature variable speed drive (VSD) technology, helping minimise energy consumption while maintaining optimal performance. Oil-free piston compressors are designed for applications requiring contamination-free air, offering a cost-effective solution for industries with high air purity demands.

Both compressor types are easy to maintain, with oil-lubricated piston compressors requiring regular oil changes and filter replacements. Oil-free piston compressors require less maintenance but still require periodic checks on air filters and valve systems to ensure reliable operation.

Our oil-lubricated piston compressors are built to handle high-pressure tasks, making them ideal for industries that require continuous air supply with minimal downtime. Oil-free piston compressors, on the other hand, are better suited for applications that demand oil-free air, such as in the medical, food processing, and electronics manufacturing sectors.

From powering air tools, blowers, and pneumatic machinery, to providing air for pressure vessels and industrial processes, piston compressors serve a wide range of industries. Choose oil-lubricated models for durability in tough environments, or oil-free compressors for air-sensitive industries where high-quality air is a must.

When choosing an air compressor, it’s important to understand the key differences between piston compressors and rotary screw compressors, as each is suited to different applications.

Piston Air Compressor

Rotary Screw Air Compressor

What size compressor you need is completely dependent on what air-operated equipment you plan on using. To work out what size would be best for you, add up the air usage of all air tools that will be used simultaneously. It’s best to add an extra 20% - 25% to allow for future usage down the track. This is only a rough guide, the best way to ensure you have the correct size machine is to request a compressed air energy audit.

No, they do not. It’s always best to check for any problems after the first start-up but after that, you are ready to go. If you do find any leaks or problems, turn the machine off and be sure to contact your product provider before operating any air compressor equipment again.

Many air compressors are able to run off generators, however, it is not recommended. If you have access to mains electricity, it is recommended you use that to power your air compressor equipment. Generators have fluctuations in power which can cause problems for compressors as they require a constant voltage to run. It is even more important for rotary screw compressors to be run off mains electricity rather than generators due to their constant operation.

If you are only using your machine occasionally, then an annual service of your compressed air equipment should be sufficient. If you are operating your air compressor routinely, then it may be best to service it quarterly. It is always recommended to do small services whenever you have the ability and time to.

If you are ever worried that your air compressor is not working the way it is intended, it is always safest to turn the unit off and have trained service technicians come and inspect the components of your compressed air system.

When looking to improve energy efficiency, customers have to look further than the air compressor and evaluate the compressed air system as a whole. The most essential part for improvement is generally your air piping system — how the compressed air is transported and used in the end application. Both the design of the distribution and the material used for piping affect energy efficiency. Consult with a compressed air specialist to see what steps can be taken to pursue reduce your energy cost. By running an energy-efficient operation, your business works toward saving money and creating a more sustainable future.

A piston air compressor, also known as a reciprocating compressor, uses a piston to compress air within a cylinder. The piston moves up and down, drawing in air, compressing it, and discharging it into a tank.

Oil-lubricated piston compressors use oil to lubricate and cool the internal components. These models are durable and efficient, suitable for general industrial applications. However, they may have slight oil contamination in the air.

Oil-free piston compressors do not use oil and produce 100% oil-free air, making them suitable for applications requiring high air purity, like medical, food, water, or electronics manufacturing.

Yes, piston compressors can be louder than rotary screw compressors, typically producing noise levels between 70-85 dBA for our high quality compressors. Proper installation and soundproofing can help reduce noise in certain applications.

Piston compressors are designed for intermittent use. Continuous operation can lead to overheating and wear. If you require continuous air supply, consider rotary screw compressors.

Oil-lubricated piston compressors generally require an oil change every 1,500 to 3,000 hours of operation, depending on use and operating conditions.

A reciprocating air compressor refers to a piston compressor that uses a back-and-forth motion of a piston to compress air. The term "reciprocating" describes the piston's motion inside the cylinder, which is what compresses air in piston compressors.

A compressor could be of various types, including rotary screw, centrifugal or scroll compressors, which use continuous rotation. A reciprocating compressor uses a back-and-forth motion to compress air, often in intermittent applications.

While piston compressors are cost-effective, they can be noisy and are not ideal for continuous operation. They also require regular maintenance, such as oil changes, and may produce oil contamination in the air, which could be problematic for certain applications. They also introduce more pronounced pulses in the compressed air and also have a much bigger vibration footprint. Vibration dampening pads are thus recommended to be installed with piston compressors.

It depends on your air tools and daily usage. Add up the CFM requirements of tools used at the same time and allow 20–25% extra capacity. If unsure, Cleveland can assess your setup and recommend the ideal unit.

An oil-injected piston compressor, also known as a reciprocating compressor, utilises a piston to compress air within a chamber. Oil is injected to lubricate, cool, and reduce wear on internal parts, resulting in efficient and long-lasting performance.

Oil-injected models utilise oil for lubrication, which can lead to trace oil contamination in the compressed air. Oil-free compressors eliminate this risk but tend to be more expensive and less durable in harsh environments. Choose based on your required air quality and end application.

Yes, reciprocating compressors are typically louder than rotary screw or scroll compressors, averaging 70-85 dBA. They're best suited to ventilated areas or separate equipment rooms if noise is a concern.

Oil-injected piston compressors are built for intermittent use. Continuous operation may lead to overheating and excessive wear leading to failure. For 24/7 air demands, we recommend a screw compressor.

Yes. Regular oil changes, air filter checks, and valve servicing are essential for maintaining performance and avoiding breakdowns. Always follow the manufacturer’s guidelines or contact us for a servicing schedule.

Not usually. If air purity is essential (e.g. food, medical, electronics), use oil-free air compressors instead. Oil-injected systems are best for general industrial use where small amounts of oil in the air are acceptable.

Oil-injected piston compressors are widely used in various industries, including:

Note: Compressed air from oil-injected systems should not come into contact with final products in industries requiring high air purity, such as medical or food processing.

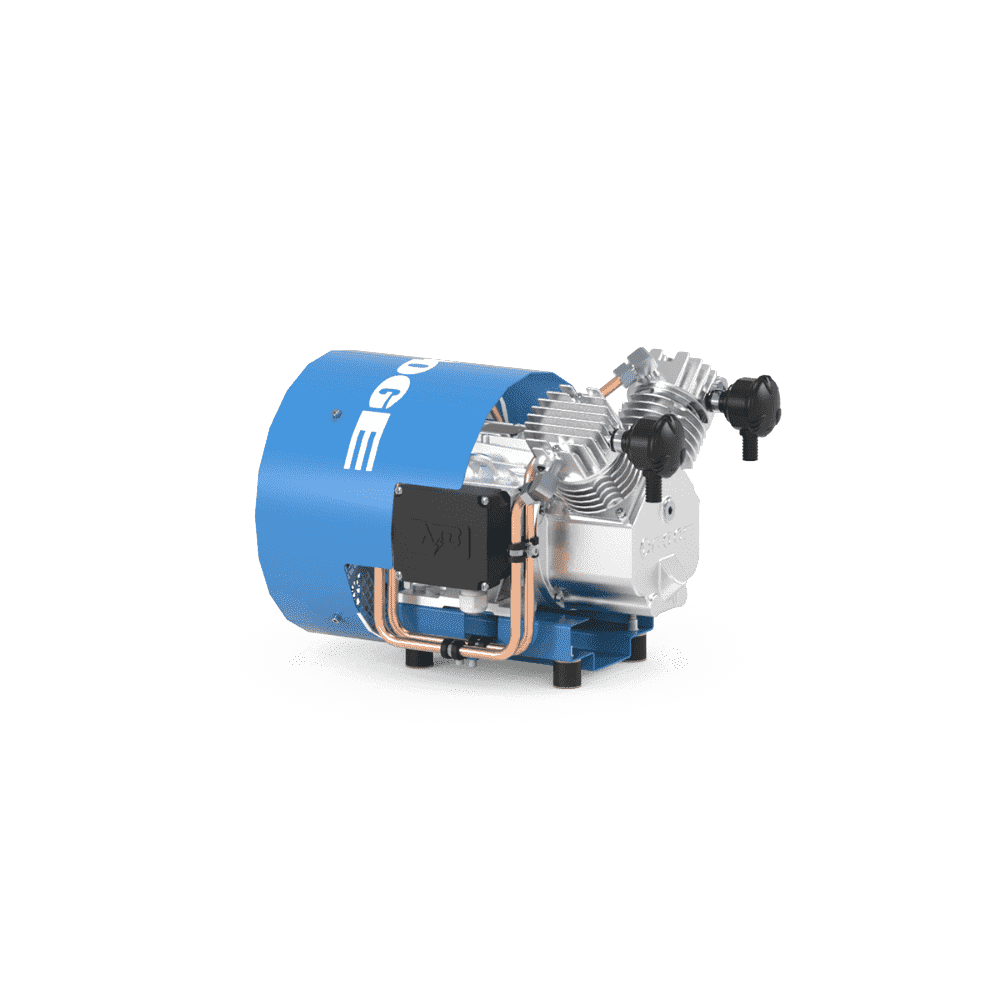

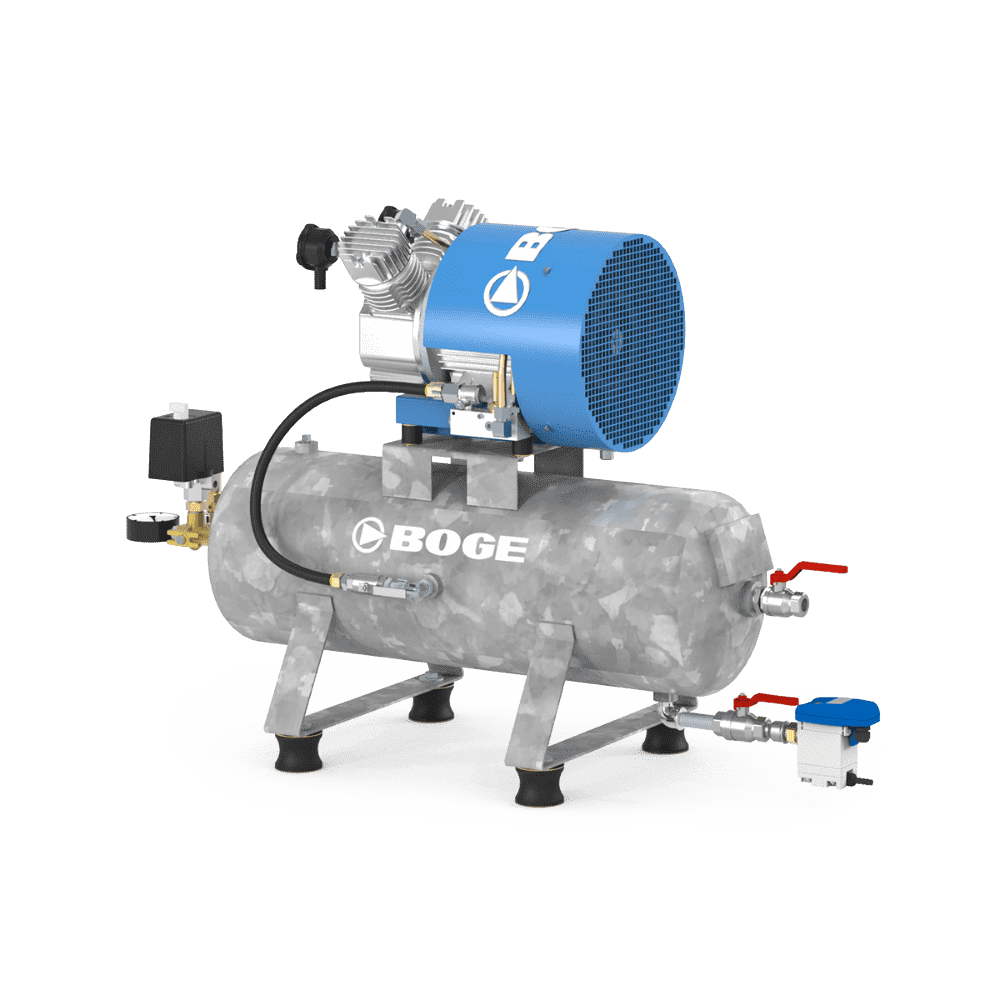

An oil-free piston compressor is a type of piston air compressor that compresses air without any oil lubrication in the compression chamber. This ensures 100% oil-free air, making it ideal for industries where contamination cannot be risked.

They are widely used in food production, pharmaceuticals, electronics manufacturing, laboratories, and medical facilities, applications where high-purity air is essential.

Yes. Modern designs with durable moving parts provide excellent reliability, even in demanding environments. However, they are typically best for intermittent use rather than 24/7 continuous duty.

Your choice depends on your air quality requirements and production needs.

Depending on the model, most operate within a range suitable for light-to-medium industrial applications. For exact figures, our team can match the right compressor to your system’s requirements.

While they can have a higher upfront cost than oil-injected models, oil-free compressors reduce the risk of product contamination and regulatory non-compliance, making them a cost-effective solution for sensitive industries.

Without oil to change, servicing mainly involves replacing filters and inspecting seals. A regular maintenance schedule ensures efficiency and prevents unexpected downtime.

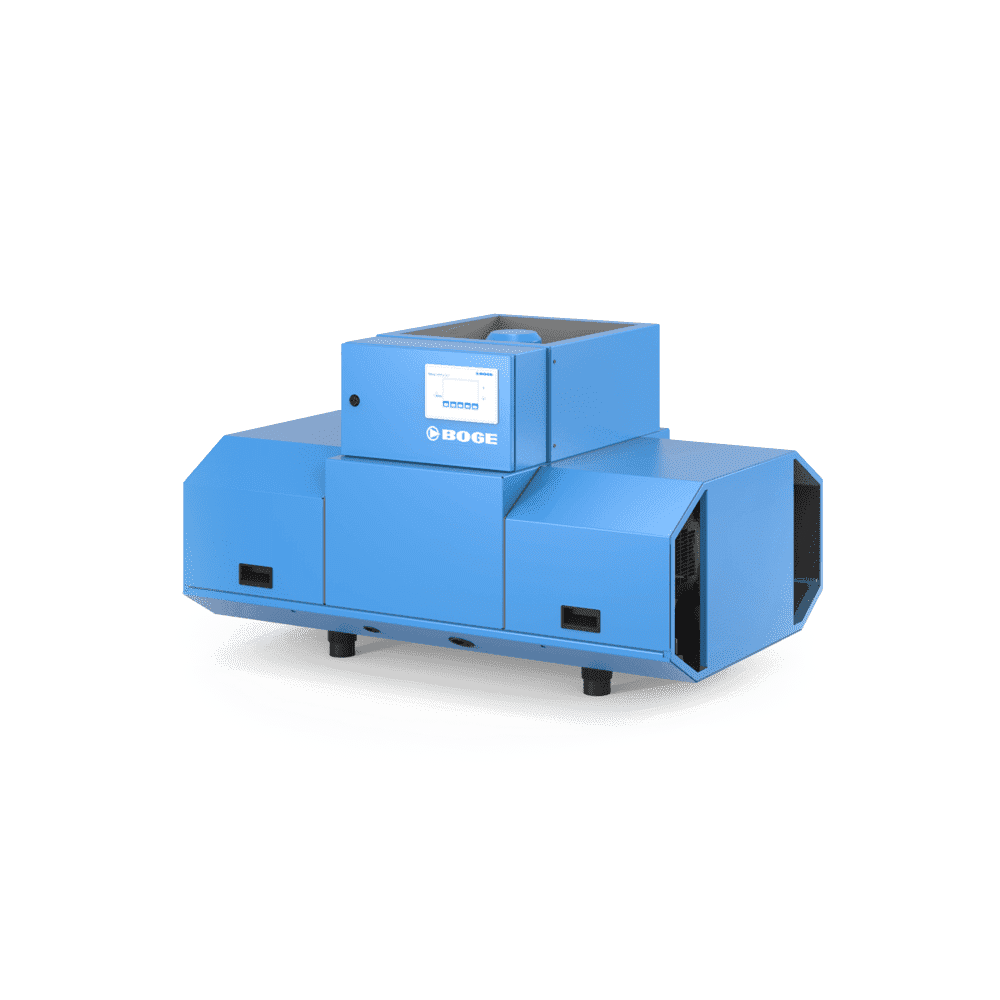

We offer a comprehensive range of oil-free piston compressors from BOGE. Our selection ensures the right fit for your application and compressed air requirements.

Cleveland Compressors has an extensive range of reliable, high-performing machines for industrial applications from some of Australia's leading brands. No matter your industry, Cleveland Compressors is bound to have the right air compressor equipment to suit your individual air demand needs.

If you want to improve your manufacturing and production processes and achieve incredible energy savings, all at a low budget, contact Australia's most reliable industrial solutions provider, Cleveland Compressed Air Services. You can do this by calling (08) 9452 3669, emailing info@ccair.net.au or contacting us online today to address your enquiry!

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.