Enquiry Form

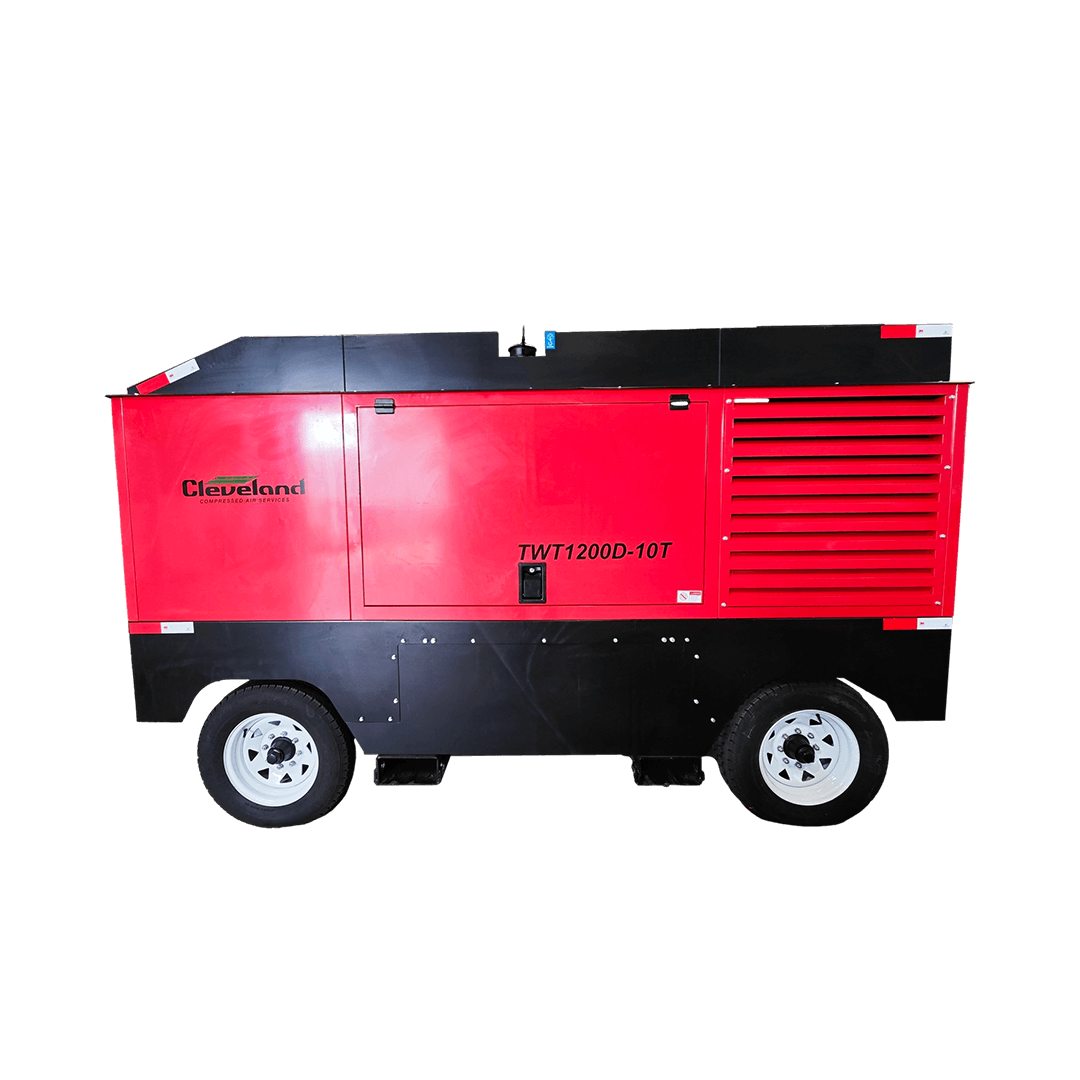

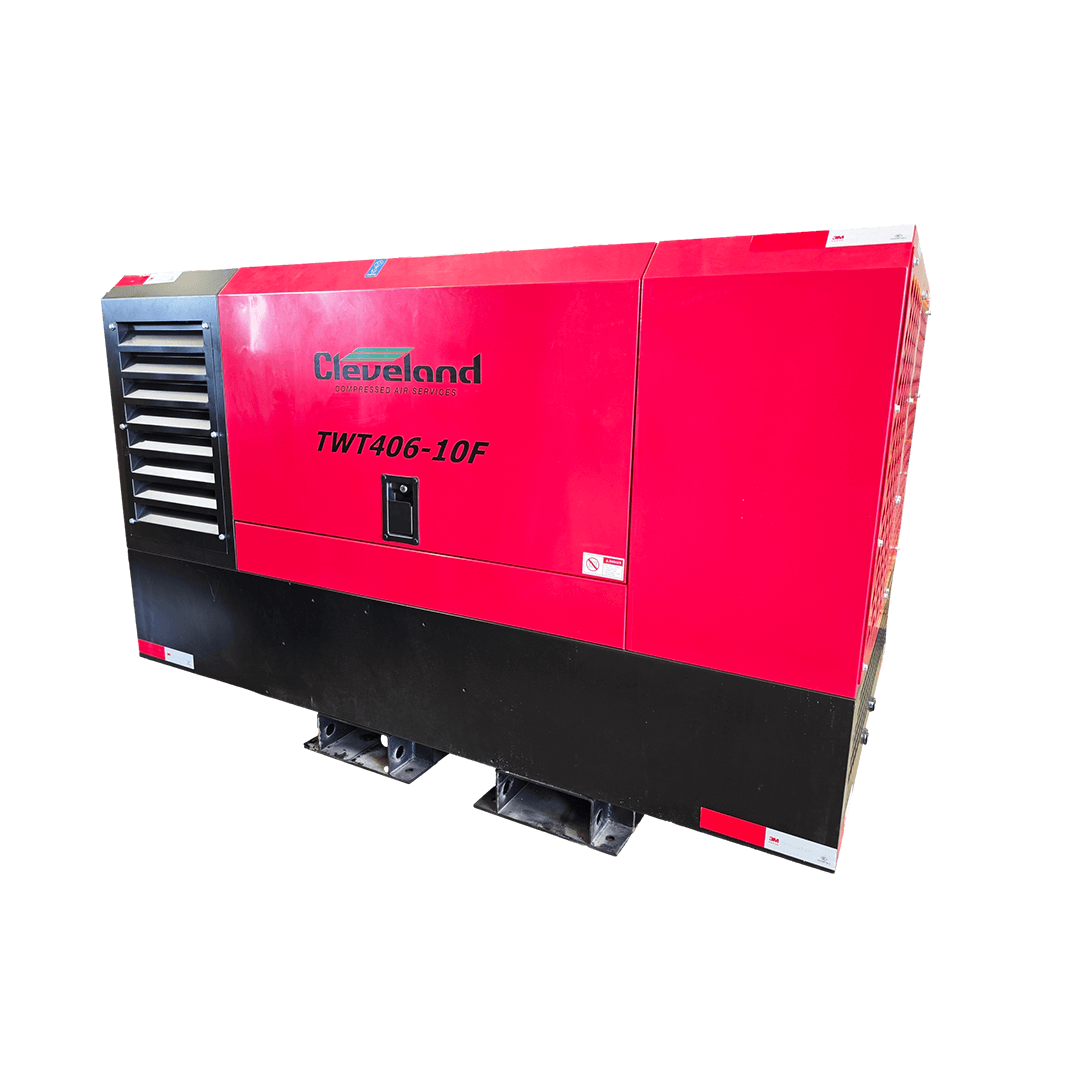

Cleveland Compressed Air Services offers comprehensive industrial air compressor systems with turnkey packages designed to meet your unique operational needs. Our range includes:

Selecting the right size air compressor is crucial to ensure optimal performance and efficiency for your specific applications. Factors such as airflow, pressure, and power sources should be considered to match the compressor capacity with your operational needs.

Not sure what the right industrial air compressor is for you? Not a problem! Cleveland’s comprehensive air compressor service will see our industrial air compressor experts visit your site and perform an audit to determine the optimum compressed air installation arrangement, saving you both time and money.

If you believe there is no substitute for quality, get in touch with a specialist supplier like Cleveland Compressors to maximise performance, reduce energy consumption, and reduce the operating costs of your industrial compressor system. Together, we can increase the reliability, efficiency and growth of your business.

Regular maintenance and repair are essential to ensure the optimal performance and longevity of industrial air compressors. Here are some common maintenance tasks to keep your compressors running smoothly:

By adhering to these maintenance practices, you can ensure that your industrial air compressors deliver reliable performance and have a longer service life.

Industrial air compressors are powerful tools that, if not handled properly, can pose safety risks. To ensure safe and effective operation, follow these essential safety precautions and guidelines:

By following these safety guidelines and staying on top of routine maintenance and repair, you can minimise risks and maintain a safe, efficient working environment when using industrial air compressors. Cleveland Compressed Air Services provides expert maintenance and repair services to keep your equipment operating at peak performance, ensuring the longevity and safety of your compressed air system.

At Cleveland Compressed Air Services, we pride ourselves on providing many businesses and industries across Australia with the best industrial compressors and services in the compressed air manufacturing industry. We offer customised solutions, high-quality compressed air products and a friendly company culture built on core values such as integrity, social responsibility and accountability.

As one of Australia’s leading providers of industrial air compressors, we recognise the importance of providing high-quality air applications and machinery, innovative solutions, and professional and timely support. If you’re interested in learning more about our range of compressed air systems and equipment, please call us today on (08) 9452 3669, email us at info@ccair.net.au or contact us online.

One of the first questions you need to ask when looking to purchase an air compressor is whether you need a piston or a rotary screw compressor. Each compressor is very different in design and is often used for different applications.

Piston Air Compressor

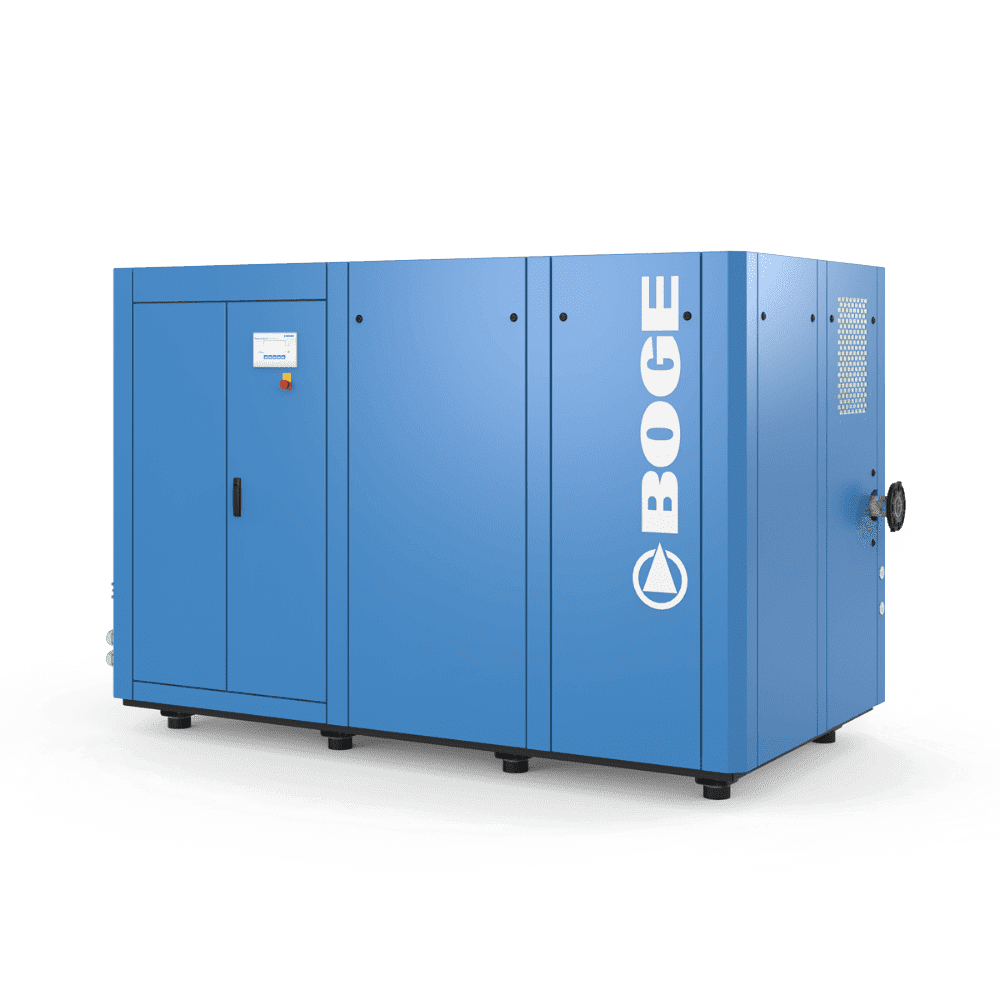

Screw Air Compressor

Oil-free compressors are designed for environments where even the smallest traces of oil are unacceptable, such as in food production. While they may have a higher initial cost and a shorter lifespan compared to oil-lubricated compressors, they provide a clean, contamination-free solution for sensitive applications. If maintaining air purity is a top priority, an oil-free compressor is the ideal choice. Here are a few key factors to consider when selecting the right air compressor for your needs.

Oil-Injected Air Compressor

Oil-Free Air Compressor

What size compressor you need is completely dependent on what air-operated equipment you plan on using. To work out what size would be best for you, add up the air usage of all air tools that will be used simultaneously. It’s best to add an extra 20% - 25% to allow for future usage down the track. This is only a rough guide, the best way to ensure you have the correct size machine is to request a compressed air energy audit.

No, they do not. It’s always best to check for any problems after the first start-up but after that, you are ready to go. If you do find any leaks or problems, turn the machine off and be sure to contact your product provider before operating any air compressor equipment again.

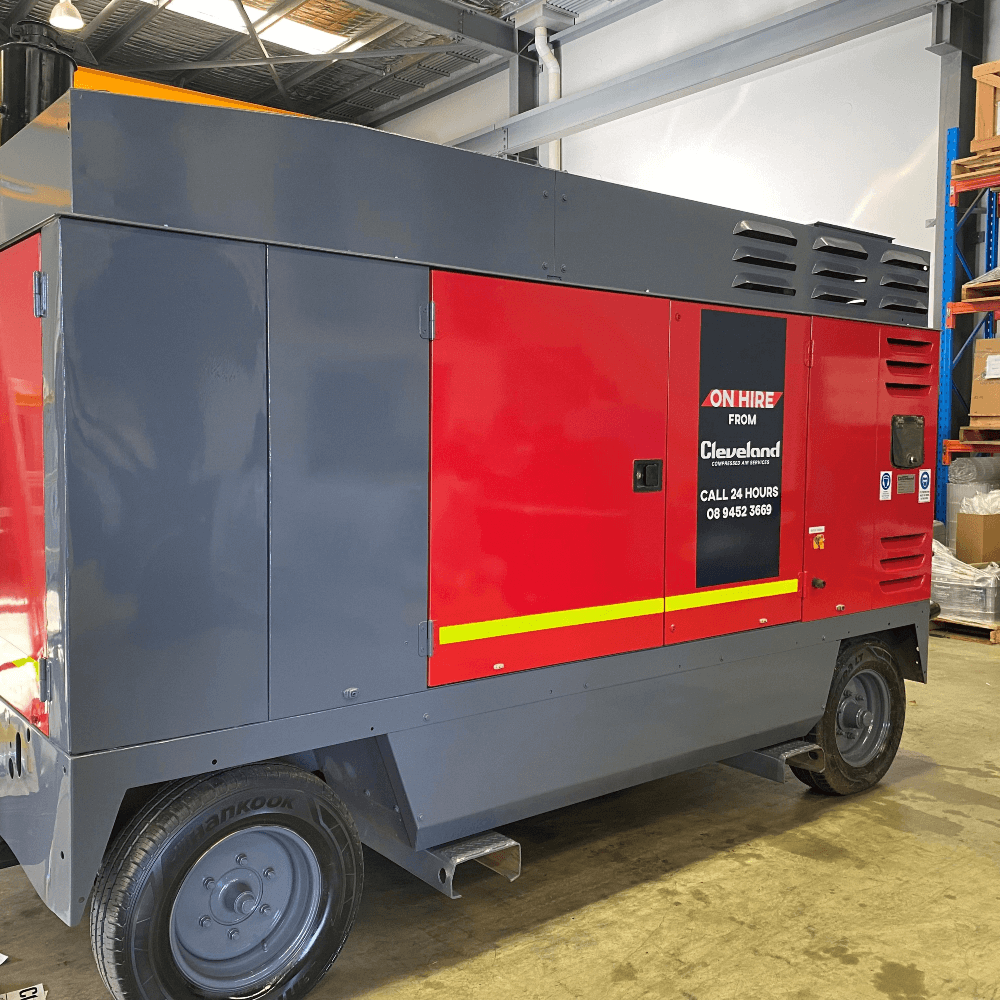

Many air compressors are able to run off generators, however, it is not recommended. If you have access to mains electricity, it is recommended you use that to power your air compressor equipment. Generators have fluctuations in power which can cause problems for compressors as they require a constant voltage to run. It is even more important for rotary screw compressors to be run off mains electricity rather than generators due to their constant operation.

Oil change frequency usually depends on the specific model of air compressor. The best way to assure it is being changed adequately is to read the recommended schedule in the owner’s manual. If you do not have access to an owner’s manual, the best way to find your answer is to contact your provider with the model number of your machine.

If you are only using your machine occasionally then annually servicing your compressed air equipment should be sufficient. If you are operating your air compressor routinely, then it may be best to service it quarterly. It is always recommended to do small services whenever you have the ability and time to.

If you are ever worried that your air compressor is not working the way it is intended, it is always safest to turn it off and have a trained industry professional come and inspect its components.

When looking to improve energy efficiency, customers have to look further than the air compressor and evaluate the compressed air system as a whole. The most essential part for improvement is generally your air piping system — how the compressed air is transported and used in the end application. Both the design of the distribution and the material used for piping affect energy efficiency. Consult with a compressed air specialist to see what steps can be taken to pursue reduce your energy cost. By running an energy-efficient operation, your business works toward saving money and creating a more sustainable future.

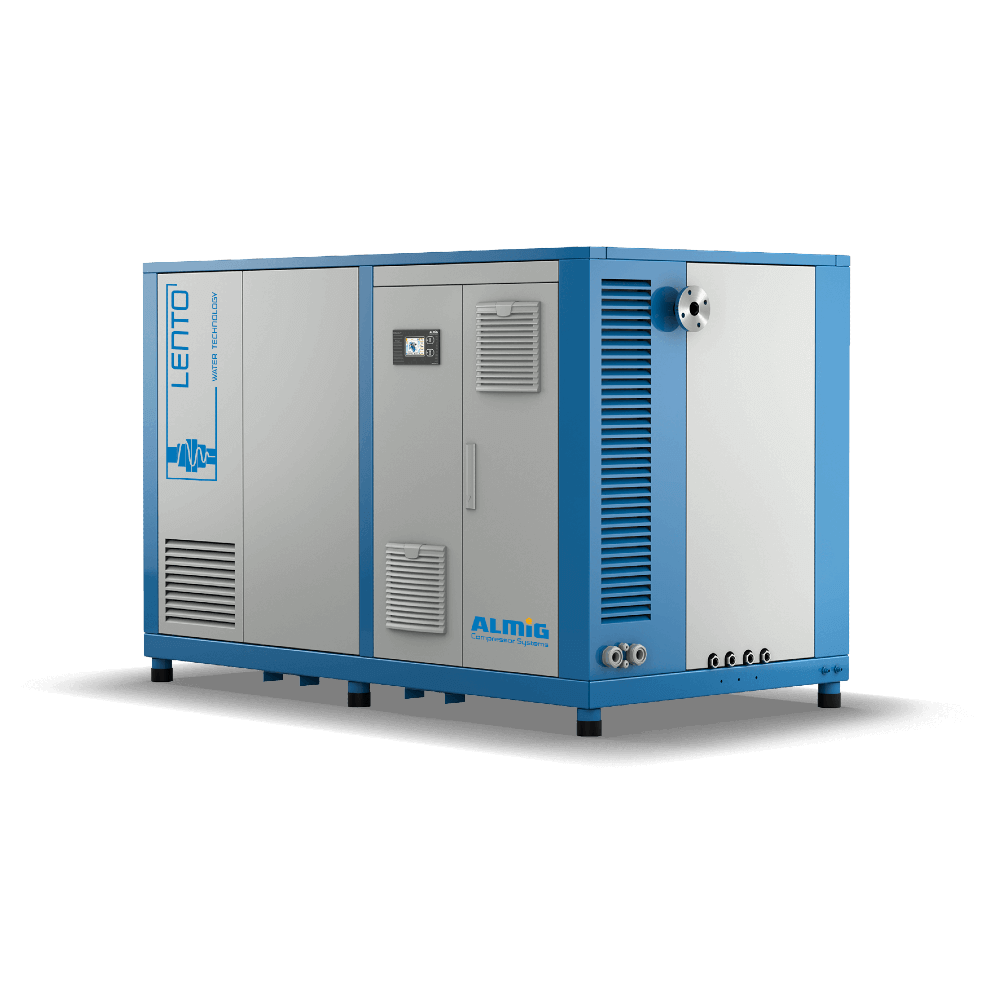

Oil-free air compressors are designed specifically to provide 100% clean air, making them the best choice for sensitive applications such as in the medical, dental, food, and beverage industries. These compressors eliminate the risk of oil contamination, which is critical in maintaining the quality and safety of your products. Additionally, oil-free compressors are engineered to deliver reliable performance with lower maintenance costs compared to oil-injected models, though they may have a shorter lifespan. Investing in an oil-free air compressor is ideal for sectors where air quality cannot be compromised.

The working pressure of oil-free air compressors varies depending on the model and application. Generally, they operate within a range of 90 to 145 psi, which is sufficient for most industrial applications. It’s important to choose a model with the appropriate working pressure to optimise your system’s efficiency and performance.

The sound level of the air compressors depends on the technology. Oil-free scroll compressors are one of the quietest air compressors around. The screw compressors are otherwise at a similar noise level, whether oil-injected or oil-free.

Investing in an oil-free air compressor is ideal for industries where air purity is critical, such as food processing, pharmaceuticals, and electronics. These air compressors provide clean, contaminant-free air, reducing the risk of product defects and ensuring compliance with stringent quality and safety standards. Choosing an oil-free solution contributes to sustainability goals and enhances a facility's environmental profile. Additionally, oil-free air compressors create less waste by reducing the need for oil and minimising disposables required after maintenance.

To optimise the efficiency of your compressed air system, it’s important to regularly review and maintain all components, including the air compressor, piping, and filtration systems. Ensuring that your system is properly engineered and designed specifically for your application can reduce energy costs and enhance overall performance. Consulting with a professional who understands the critical aspects of compressed air systems can help you achieve the best results.

Oil-free air compressors come with various professional features that enhance their reliability and performance. These compressors are also equipped with technology that ensures compliance with ISO Class 0 air quality standards, making them suitable for the most demanding applications. Additionally, oil-free air compressors are ideal for critical applications, ensuring reliable and contaminant-free air in demanding industries.

At Cleveland Compressed Air Services, we offer comprehensive support for our oil-free air compressor range. Our services include installation, service, maintenance, and repairs to ensure your compressor operates at peak efficiency. We understand the importance of reliability in your operations, which is why our products and services are designed to meet the highest standards. Whether you’re looking for a new system or need support with your existing setup, our team is here to help.

An oil-injected compressor uses oil in the compression chamber to lubricate, seal, and cool the air during compression. This design improves your energy efficiency, reduces wear, and supports consistent performance, making oil-injected air compressors ideal for continuous use in general manufacturing, workshops, and more.

An oil-free air compressor produces 100% oil-free air, eliminating any risk of oil contamination in your compressed air. In contrast, an oil-injected air compressor uses oil for lubrication, which may carry over into your compressed air system. The right choice depends on your air quality requirements and specific application requirements.

Choosing between an oil-free and oil-injected compressor depends on your air quality needs, budget, and, of course, application.

If you need a completely oil-free environment, such as in food production, pharmaceuticals, or medical procedures, an oil-free compressor is the only suitable option. These systems prevent oil carryover that could contaminate products or processes.

Oil-Injected Air Compressors

Oil-Free Air Compressor

While oil-free air compressors provide clean, contamination-free air, there are a few trade-offs to consider. They are typically more expensive to purchase and may have a shorter lifespan in high-demand or continuous-use environments. Some models may require more frequent filter changes or specialist servicing to maintain performance.

In contrast, oil-injected compressors use oil to cool and lubricate internal components, which can improve energy efficiency and extend the life of the machine. However, they require more maintenance and are not suitable for applications that demand completely oil-free air.

Oil-injected compressors are widely used in general manufacturing, automotive, construction, and heavy-duty compressed air applications. Understanding specific application requirements is crucial when choosing between oil-free and oil-injected compressors. They’re ideal where air quality is important but not critical and where efficiency, reliability, and lower cost of ownership matter most to your operation.

The energy efficiency of your air compressor depends not only on the unit itself but also on how your entire compressed air network is designed and maintained. A well-designed air piping system plays a crucial role in reducing pressure drops, minimising leaks, and maintaining consistent air temperature and flow.

Oil-injected rotary screw compressors are often among the most efficient options, especially when paired with an optimised air piping system. For the best results, have your compressed air system audited to assess how your compressed air is distributed and used. Improving layout, materials, and pipe diameter can lead to significant energy savings and enhanced system performance.

Oil-injected screw compressors use internal oil filters, oil coolers, and oil separators to minimise oil contamination in your compressed air. With regular maintenance, you can ensure optimal air quality and protect your downstream equipment.

The size of the compressor you need is completely dependent on the air-operated equipment you plan on using. To work out what size would be best for you, add up the air usage of all air tools that will be used simultaneously. It’s best to add an extra 20-25% to allow for future usage down the track. This is only a rough guide, the best way to ensure you have the correct size machine is to get a compressed air energy audit.

No, they don’t. You should always check for any problems after the first start-up. However, once that’s done, you’re good to go. If you notice any leaks or issues, turn off your compressor and contact your product provider before operating any air compressor equipment again.

Many air compressors are able to run off generators however, it is not recommended. If you have access to mains electricity, it is recommended that you use that to power your air compressor equipment. Generators have fluctuations in power, which can cause problems for compressors as they require a constant voltage to run. It is even more important for rotary screw compressors to be run off mains electricity rather than generators due to their constant operation and the need for a stable power supply for the motor.

The frequency of oil change depends on your air compressor model, how you use it and the age of the machine. The best way to ensure it is being changed adequately is to have your oil-injected air compressor serviced regularly by a professional air compressor servicing business.

The timing of your air compressor maintenance or servicing will depend on your model of oil-injected air compressor, as well as your specific system setup and usage. Regardless of the exact intervals, regular servicing is crucial for maintaining the reliability of your oil-injected compressor.

You should have the oil filters, oil separator, and thermostatic valve checked regularly and have the oil changed based on usage and model. Always follow your manufacturer’s recommendations or speak with a specialist to create an air-compressor servicing schedule that suits your needs.

A scroll compressor uses two spiral elements, one fixed and one orbiting, to compress air. This oil-free design offers a quiet, smooth and energy-efficient alternative to reciprocating compressors, with fewer moving parts and less wear. It’s ideal for delivering clean, reliable compressed air in commercial environments.

A scroll air compressor works by squeezing air between two spiral-shaped parts, one stays still while the other moves in a circle. This smooth motion means there’s less noise and no pulsing, so the airflow stays steady. It’s a quiet, compact, and reliable option when you need clean, oil-free air for things like medical, food, or lab work.

Both get used in industrial or commercial settings, but a scroll compressor is typically quieter, has fewer moving parts, and delivers oil-free air, making it ideal for clean applications. A rotary screw compressor, handles higher volumes and pressures and is better for heavy-duty or continuous-use scenarios.

While scroll compressors are great for certain applications, they usually have a lower discharge pressure than piston or rotary screw models and may not be ideal for high-demand operations or hot environments. They’re generally best suited for low to medium-duty cycles, though some models can continuously operate when correctly sized and maintained in weather-controlled environments.

Oil-free scroll air compressors deliver excellent energy efficiency with fewer moving parts and no oil-based lubrication. Their compact and friction-reducing design helps lower energy consumption and ongoing energy costs for low or partial load applications For full load or demanding applications, oil free water injected screw compressors are unmatched in energy efficiency and air quality.

Scroll air compressors maintain high air quality through their oil-free design and the use of advanced air filters. With no oil filter or lubricating oil required, there's no risk of oil contamination, making them ideal for cleanroom and sensitive production environments.

Oil-free scroll compressors are ideal for industries where clean or oil-free, dry compressed air is essential. These include:

Their quiet operation, compact footprint, and low maintenance make them perfect for environments with strict air purity standards.

If your scroll compressor is not starting, making unusual noises, overheating, or delivering reduced air pressure, it may need a service. Turn off the unit and have it inspected by a qualified air compressor technician to prevent further damage to your compressed air system.

While it is technically possible, using a generator to power a scroll air compressor is not recommended. Scroll compressors are quite sensitive when it comes to an inconsistent power supply. Plus, voltage fluctuations can interfere with the orbiting scroll mechanism or electronic controls, leading to reduced performance, premature wear, or system failure. Compressors require a stable, constant voltage to operate efficiently.

If you have access to mains electricity, it is always best to use it. This ensures consistent performance, maintains energy efficiency, and protects the internal components from potential damage. The same principle applies to rotary screw compressors, which also rely on steady power to support continuous operation and avoid issues with the drive motor.

Your air compressor servicing or maintenance timing really depends on your specific scroll compressor model, unique system setup, and how often the scroll compressor is used. While oil-free scroll compressors are known for their low-maintenance design, regular servicing is still essential to ensure consistent performance, air quality, and long-term reliability.

You should have the air filters, non-return valve, and system controls checked periodically and any worn components replaced according to the manufacturer’s guidelines. Our team at Cleveland Compressed Air Services can provide expert servicing tailored to your usage and system requirements. Contact our team to book a service or book in a maintenance schedule that suits your needs.

The size of the air compressor depends on the types of tools you use and the scale of your operations. For most mechanic shops, a rotary screw compressor with a capacity of 5.5kW to 15kW is suitable. Always consider future expansion by adding 20-25% to your estimated capacity needs.

To operate power tools efficiently, you'll need a compressor with sufficient tank capacity and pressure. For most tools, a workshop air compressor with 90 to 120 psi and a tank capacity of 50 to 100 litres is recommended. Check your tools' specifications and choose a compressor that meets or exceeds those requirements.

Rotary screw compressors provide a continuous air supply, making them ideal for workshops with high-demand applications. They are quieter than piston compressors, offer greater longevity, and require less maintenance, making them a cost-effective solution for busy environments.

Yes, workshop air compressors are perfect for spray painting applications. Their ability to deliver consistent pressure ensures smooth and even paint finishes, making them ideal for automotive painting and other similar tasks. Our workshop air compressors also come equipped with an air dryer, which removes moisture from the air to prevent imperfections in the paint finish, ensuring a professional result.

Regular maintenance is crucial for keeping your air compressor in peak condition. If you use your compressor daily, consider quarterly servicing. For occasional use, annual maintenance may be sufficient. Minor services can be done as needed to ensure reliability.

Oil-free compressors generally require more frequent maintenance compared to oil-injected models. While they eliminate the need for oil changes, components such as filters, seals, and air dryers must be checked and replaced regularly to maintain efficiency. The exact maintenance schedule depends on usage, but routine servicing is recommended every 1,500 to 4,000 hours of operation, depending on model and environment.

While oil-free air compressors reduce the risk of oil-related contamination and maintenance issues, they may have a shorter lifespan due to increased wear on components. Proper maintenance, including regular filter changes and moisture management, is key to maximising their longevity.

If you’re worried that your air compressor isn’t working as it should, turn it off immediately and have a qualified air compressor technician inspect it before continuing use.

Cleveland Compressors have an extensive range of reliable, high-performing machines for industrial applications from some of Australia's leading brands. No matter your industry, Cleveland Compressors is bound to have the right air compressor equipment to suit your individual air demand needs. If you want to improve your manufacturing and production processes and incredible energy savings, all at the lowest cost, contact Australia's most reliable industrial solutions provider, Cleveland Compressed Air Services by calling (08) 9452 3669, emailing info@ccair.net.au or contacting us online today!

We believe that your success is our success. That is why we provide top-notch solutions and support to businesses using our quality products, whether through purchase or hire.